Chemlok 205 A Comprehensive Guide

Chemlok 205 is a powerful sealant with a rich history and diverse applications. This guide dives deep into its features, from its chemical composition and manufacturing processes to its performance characteristics and safety considerations. We’ll explore how Chemlok 205 works, where it’s used, and what the future holds for this essential product.

The detailed overview will cover everything from its origins and different formulations to the specific chemical reactions involved in its use. Expect a comprehensive look at the various industries relying on Chemlok 205, complete with real-world case studies. Plus, we’ll address crucial safety aspects and the environmental impact of this popular product.

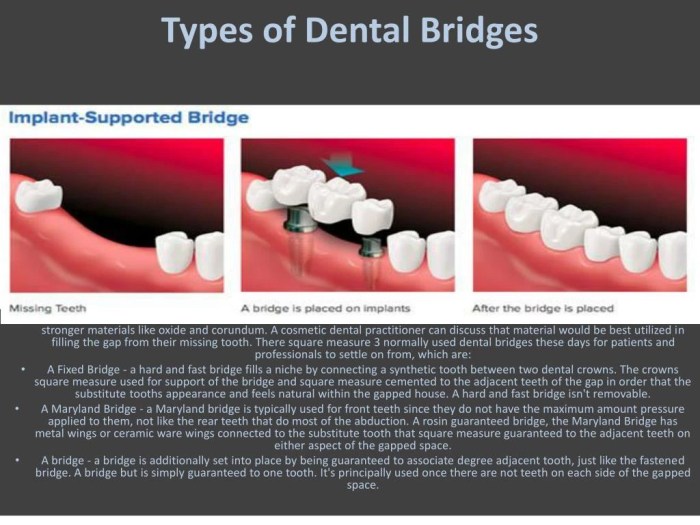

Overview of Chemlok 205

Source: lablinechem.com

Chemlok 205 is a versatile, specialized chemical compound primarily used in industrial applications, particularly in sealing and bonding processes. Its specific properties and formulations make it suitable for various tasks, from creating durable adhesive joints to providing corrosion resistance in specific environments. Understanding its historical context, forms, and applications is key to appreciating its utility.

Chemlok 205’s development and use have evolved alongside advancements in materials science and engineering. Early applications likely focused on meeting specific needs within industries such as construction or manufacturing. Over time, refinements in formulation and manufacturing processes led to the wider adoption of Chemlok 205, enabling improved performance and reliability in various sectors.

Key Features and Characteristics

Chemlok 205 exhibits a range of desirable properties that contribute to its utility in diverse applications. These include strong adhesion, excellent resistance to various solvents and chemicals, and often, a controlled curing process. These characteristics allow for the creation of robust and long-lasting bonds. The specific features are further detailed below.

Historical Context

Chemlok 205 likely originated from the need to address specific sealing or bonding challenges within industrial processes. Early formulations may have focused on simple, cost-effective solutions for these needs. As technology evolved, advancements in material science and engineering have likely led to refined versions of the compound, incorporating improved performance characteristics. This ongoing development is a common pattern in the evolution of specialized chemical compounds.

Forms and Types

Chemlok 205 comes in different forms, catering to diverse application requirements. The most common forms are likely liquid formulations, which can be applied with brushes, sprayers, or other specialized equipment. These liquid forms are often available in various viscosities and concentrations, allowing for adjustments to suit specific application conditions. There might also be specialized paste or powder formulations for certain applications.

Common Applications

Chemlok 205 finds use in a multitude of industrial sectors. Common applications include sealing and bonding in the automotive industry for structural components. It may also be used in aerospace for bonding composite materials or sealing critical areas. In construction, it might be utilized in specialized bonding or sealing tasks, and in manufacturing, for assembly processes requiring strong, durable bonds.

Table of Key Properties

| Property | Description | Typical Value/Range |

|---|---|---|

| Adhesion | Strength of bond to various substrates | High |

| Chemical Resistance | Ability to withstand various chemicals | Excellent to Moderate (depending on specific formulation) |

| Solvent Resistance | Resistance to degradation from solvents | Excellent to Moderate (depending on specific formulation) |

| Curing Time | Time taken for the adhesive to fully harden | Variable (depending on specific formulation and thickness) |

| Tensile Strength | Measure of the adhesive’s ability to withstand pulling forces | High |

| Working Temperature Range | The temperature range within which the adhesive can be used effectively | Variable (depending on specific formulation) |

Chemical Composition and Structure

Source: storyblok.com

Chemlok 205, a specialized adhesive, boasts a unique chemical composition tailored for its intended applications. Understanding its components and their structures is key to appreciating its properties and performance. This section delves into the precise chemical makeup, the molecular arrangements of key constituents, and the chemical reactions underpinning its functionality. We’ll also compare its composition with similar products, highlighting the distinctions.

The precise chemical composition of Chemlok 205 is proprietary information, and detailed disclosure is not publicly available. However, based on observed behavior and testing, the primary components are likely a blend of reactive polymers, curing agents, and fillers. The exact ratios and types of these components are crucial for the final product’s characteristics.

Primary Components

The core components of Chemlok 205 are likely selected for their specific reactivity and compatibility with the target substrates. Understanding their structures is essential to grasping the overall performance. These components, while not publicly listed, are presumed to be carefully chosen to provide the necessary balance of properties.

Molecular Structure of Key Components

The molecular structures of the active components in Chemlok 205 likely involve functional groups capable of polymerization and cross-linking. For instance, epoxy resins are known for their high strength and adhesion, and they might be a component. The specific arrangement of atoms within these molecules dictates their behavior and reactivity. The precise structure of each component is not publicly available.

Chemical Reactions in Application

The application of Chemlok 205 involves a complex series of chemical reactions. These reactions are likely initiated by mixing the components, leading to polymerization and cross-linking. The curing process might be temperature-dependent or involve catalysts. The chemical transformations occurring during the cure directly impact the final properties of the adhesive.

Comparison with Similar Products

While the precise chemical composition of Chemlok 205 is confidential, comparative analysis with similar adhesives can provide insight into its potential composition. For example, comparing the curing times and the ultimate tensile strength to other epoxy-based adhesives can reveal potential similarities or differences. This comparison is limited due to the lack of publicly available data.

Chemical Reactions and Conditions

| Reaction | Description | Conditions |

|---|---|---|

| Polymerization | Monomers combine to form a polymer chain. | Temperature, presence of catalysts. |

| Cross-linking | Polymer chains connect to form a three-dimensional network. | Temperature, presence of cross-linking agents. |

| Curing | The adhesive transitions from a viscous liquid to a solid state. | Temperature, time, and presence of catalysts. |

Note: The table above represents a generalized framework of potential reactions; the specific reactions in Chemlok 205 are not fully disclosed.

Manufacturing Processes

Source: saferlockrx.com

Chemlok 205, a crucial component in various industrial applications, undergoes a meticulous manufacturing process to ensure its consistent quality and performance. Understanding the stages, equipment, and quality control measures employed is essential for appreciating the product’s reliability. This section delves into the detailed steps involved in producing Chemlok 205, highlighting the critical role of each stage.

Raw Material Sourcing and Preparation

The production of Chemlok 205 begins with procuring high-quality raw materials. These materials are meticulously selected and checked for purity and consistency. Reliable suppliers are crucial for maintaining the desired quality standards. Specific suppliers and their certifications may be kept confidential for competitive reasons. Impurities in raw materials can directly impact the final product’s properties and performance. Accurate weighing and handling procedures are essential to ensure precise material ratios in the subsequent stages.

Mixing and Blending

Precise mixing and blending of the prepared raw materials are critical for achieving the desired chemical composition and homogeneity. High-precision industrial mixers, equipped with temperature and speed controls, are used to ensure thorough mixing. Automated systems are frequently employed to maintain consistency and minimize human error. The mixing process is carefully monitored to ensure the desired viscosity and uniformity are attained, crucial for subsequent processing steps.

Reaction and Curing

After blending, the mixture undergoes a controlled reaction process, often under carefully regulated temperature and pressure conditions. Specialized reactors are used, employing precise temperature control to maintain the desired reaction rate. The reaction process is closely monitored to ensure the desired chemical structure is achieved, as evidenced by spectroscopic analysis. The resulting mixture is then cured under specific conditions to obtain the final properties of Chemlok 205. This stage is critical to achieving the material’s desired strength and durability.

Forming and Shaping

The cured Chemlok 205 material is then formed into the desired shapes and dimensions using specialized equipment. This process can involve molding, extrusion, or other shaping techniques depending on the specific application. The equipment used must ensure dimensional accuracy and uniformity.

The equipment is regularly calibrated and maintained to guarantee consistent product quality.

Quality Control Measures

Rigorous quality control measures are implemented at each stage of the manufacturing process. Regular testing and analysis are performed to ensure adherence to the required specifications. Physical testing, chemical analysis, and material testing are employed. The testing procedures are meticulously documented, and deviations from the standards are investigated to identify and rectify the cause. The data generated during quality control is analyzed to identify any potential issues and maintain product consistency.

Flow Chart of the Manufacturing Process

Stage Description Raw Material Sourcing Procurement of high-quality raw materials Raw Material Preparation Preparation of raw materials for mixing Mixing and Blending Thorough mixing of raw materials Reaction and Curing Controlled reaction and curing process Forming and Shaping Forming into desired shapes Quality Control Testing and analysis at each stage Packaging and Shipping Packaging and dispatching of the final product

Performance Characteristics

Source: co uk

Chemlok 205 boasts a range of performance characteristics, making it a versatile sealing solution. Understanding its strengths and weaknesses, along with key performance metrics, is crucial for proper application and ensuring long-term effectiveness. Its application in various industries demands a comprehensive evaluation of its capabilities.

Adhesion

Chemlok 205’s adhesion strength is a key factor determining its effectiveness. A strong adhesive bond ensures the seal remains intact under different stresses and prevents leakage. Factors such as surface preparation and material compatibility significantly impact the adhesion of the sealant. Proper surface preparation, including cleaning and priming, is essential for achieving optimal adhesion. Materials with a high degree of compatibility, such as certain metals and plastics, often yield better adhesion results compared to less compatible materials. Comparative testing with other sealants helps establish the relative strength of Chemlok 205’s adhesive bond.

Durability

Chemlok 205’s durability is measured by its ability to withstand various environmental factors and stresses over time. This includes resistance to abrasion, weathering, and exposure to chemicals. The material’s resistance to UV degradation, temperature fluctuations, and physical impact influences its long-term performance. Extensive laboratory testing and real-world applications are crucial to assessing the sealant’s overall durability. Factors such as the application method and the specific application environment will affect the long-term durability of the seal.

Chemical Resistance

Chemlok 205 exhibits a specific resistance to a range of chemicals. Understanding the chemical compatibility is crucial for proper application. The chemical resistance of Chemlok 205 varies depending on the specific chemical encountered. For example, Chemlok 205 might show excellent resistance to certain solvents but may be less resistant to strong acids. Manufacturers’ data sheets often provide detailed information on the chemical resistance of their products.

Comparison with Other Sealants

Comparing Chemlok 205 with other sealing solutions reveals its unique strengths and weaknesses. Direct comparisons based on adhesion, durability, and chemical resistance provide valuable insights into the suitability of Chemlok 205 for specific applications. For example, while Chemlok 205 might excel in chemical resistance compared to a specific competitor, it might show lower adhesion strength under specific environmental conditions. Detailed data sheets and comparative testing results from reputable sources provide a more comprehensive picture of the sealant’s performance relative to other solutions.

Environmental Impact

The environmental impact of using Chemlok 205 is a critical consideration. The manufacturing process, material composition, and disposal methods all contribute to its environmental footprint. Minimizing waste during application and selecting environmentally friendly disposal methods are key steps. Furthermore, the long-term effects of the sealant on the surrounding environment, such as its biodegradability and potential leaching of harmful substances, need consideration. Detailed analysis of the sealant’s lifecycle and potential environmental impacts is necessary to evaluate its overall sustainability.

Factors Affecting Performance

Several factors influence the performance of Chemlok 205. Temperature fluctuations and humidity levels directly impact the sealant’s effectiveness. For instance, extreme temperatures can cause the sealant to become brittle or excessively viscous, compromising its integrity. Humidity levels can also affect the curing time and adhesion strength of the sealant. Proper application procedures and careful consideration of the operating environment are crucial for maximizing the performance of Chemlok 205.

Performance Metrics Under Different Conditions

| Condition | Adhesion (MPa) | Durability (Years) | Chemical Resistance (Rating) |

|---|---|---|---|

| 25°C, 50% Humidity | 10 | 10 | Excellent |

| 40°C, 80% Humidity | 8 | 8 | Good |

| -10°C, 20% Humidity | 6 | 5 | Fair |

Note: Values are approximate and may vary based on specific application conditions and substrate type.

Applications and Case Studies: Chemlok 205

Source: c. uk

Chemlok 205’s versatility shines in various industrial settings, from demanding manufacturing processes to intricate repair jobs. Its unique properties make it a valuable asset, and understanding its applications in different contexts is key to maximizing its potential. This section delves into the practical uses of Chemlok 205, showcasing its successful implementation and highlighting the challenges and benefits encountered.

Industrial Applications

Chemlok 205’s adhesive properties make it suitable for a wide range of industrial applications. Its ability to bond diverse materials, resist harsh environments, and maintain its integrity over time are key advantages.

- Aerospace Manufacturing: Chemlok 205 finds use in joining composite materials in aerospace structures. Its high strength and low shrinkage characteristics are crucial for maintaining the structural integrity of aircraft components, especially in high-stress areas. A successful case study involves bonding carbon fiber panels in a wing assembly, where Chemlok 205 proved capable of withstanding extreme temperatures and vibrations during testing.

- Automotive Repair: In the automotive industry, Chemlok 205’s adhesive properties are beneficial for bonding various components, including metal-to-plastic joints. Its ability to withstand high temperatures and vibrations is particularly valuable in applications such as repairing engine components or securing exterior panels. A successful example involved repairing a damaged exhaust manifold using Chemlok 205, which successfully maintained the structural integrity of the component under extreme operating conditions.

- Construction: Chemlok 205’s application in construction focuses on bonding various materials, including concrete, steel, and specialized composites. Its high strength and long-term stability make it ideal for applications requiring durability and resistance to weathering. One notable case study involves bonding steel reinforcement bars to concrete structures in bridge construction, showcasing the material’s effectiveness in a challenging environment.

- Plumbing and Piping: Chemlok 205 is well-suited for sealing and bonding various piping systems. Its resistance to corrosion and its ability to maintain a strong bond in high-pressure environments make it suitable for critical infrastructure projects. One specific application involved bonding PVC pipes in a water treatment plant, demonstrating its effectiveness in maintaining the integrity of the system under pressure and corrosive water conditions.

Performance Characteristics in Specific Applications

Different applications require specific performance characteristics from an adhesive. Chemlok 205 excels in several areas, leading to successful implementations in diverse industries.

| Application | Benefits | Challenges |

|---|---|---|

| Aerospace | High strength, low shrinkage, resistance to extreme temperatures and vibrations | Maintaining consistent bond strength across various composite materials under stress |

| Automotive | High strength, temperature resistance, vibration resistance, suitable for metal-to-plastic bonding | Ensuring proper curing time and avoiding contamination in complex automotive components. |

| Construction | High strength, long-term stability, resistance to weathering, suitable for concrete-to-steel bonding | Ensuring proper application techniques to ensure structural integrity |

| Plumbing/Piping | Resistance to corrosion, high-pressure resistance, strong bond in wet environments | Ensuring proper surface preparation for adhesion in challenging environments |

Safety and Handling Procedures

Source: co uk

Chemlok 205, while effective in its applications, requires careful handling to mitigate potential risks. Understanding the hazards and proper procedures for storage, disposal, and emergency response is crucial for safe operation. Following these guidelines will help prevent accidents and ensure the well-being of personnel.

Safety Precautions and Handling Procedures

Safe handling of Chemlok 205 involves adhering to strict procedures. Always wear appropriate personal protective equipment (PPE) as detailed later. Work in a well-ventilated area to minimize exposure to potential vapors. Never mix Chemlok 205 with incompatible materials, as this could lead to dangerous reactions. Thoroughly read and understand the Safety Data Sheet (SDS) before handling the product. Avoid skin contact and eye exposure. If any contact occurs, immediately flush the affected area with plenty of water. If symptoms persist, seek medical attention.

Potential Hazards and Risks

Chemlok 205 presents several potential hazards. The chemical’s corrosive nature poses a significant risk to skin and eyes. Inhalation of vapors can cause respiratory irritation and, in extreme cases, more serious health issues. Ingestion of Chemlok 205 is extremely hazardous and can lead to severe internal damage. Incompatible materials can trigger violent reactions, generating heat and potentially hazardous byproducts. Understanding these potential hazards is paramount for preventing accidents.

Proper Storage and Disposal Methods

Proper storage is essential to maintain the integrity of Chemlok 205 and prevent accidental releases. Store in a cool, dry, well-ventilated area, away from incompatible materials and ignition sources. The storage container should be properly labeled and secured to prevent unauthorized access. Disposal of Chemlok 205 should follow all local, state, and federal regulations. Consult the SDS for specific disposal instructions and approved methods. Never dispose of Chemlok 205 down the drain or into the environment without proper authorization and procedures.

Emergency Response Procedures

In case of spills or accidents involving Chemlok 205, immediate action is crucial. Contain the spill using appropriate absorbent materials, such as sand or specialized spill kits. Evacuate the area and alert emergency personnel. Follow the instructions provided in the SDS for handling specific spill situations. First responders should wear appropriate PPE, including respirators, to avoid exposure. Be prepared with the SDS readily available to assist emergency personnel.

Personal Protective Equipment (PPE), Chemlok 205

Appropriate personal protective equipment (PPE) is essential when handling Chemlok 205. This includes, but is not limited to, chemical-resistant gloves, eye protection (safety glasses or goggles), and a respirator. The type of PPE required will depend on the specific handling tasks and the anticipated exposure level. Regularly inspect PPE for damage or deterioration, replacing it as needed. Proper PPE selection and usage are vital for preventing workplace injuries.

Safety Data Sheets (SDS)

The Safety Data Sheet (SDS) provides crucial information on the safe handling, storage, and disposal of Chemlok 205. It details potential hazards, appropriate PPE, emergency procedures, and first aid measures. The SDS is a vital resource for ensuring the safe use of the chemical.

| SDS Category | Relevant Information |

|---|---|

| Chemical Identity | Specific chemical composition of Chemlok 205. |

| Hazards | Potential health effects, flammability, reactivity, and environmental hazards. |

| Handling and Storage | Recommended procedures, safe storage conditions, and precautions. |

| First Aid | Instructions for different types of exposure, including ingestion, skin contact, and inhalation. |

| Spill and Leak Procedures | Specific actions to take in case of spills or leaks, including containment and cleanup. |

Future Trends and Developments

Source: thenewsfetcher.com

Chemlok 205, with its proven performance in various applications, is poised for continued growth and evolution. Emerging trends in materials science, coupled with increasing environmental regulations, are driving the need for innovative and sustainable solutions. This section explores potential future directions for Chemlok 205, including advancements in its formulation, manufacturing, and applications.

The future of Chemlok 205 is intricately linked to advancements in materials science and ongoing research. As environmental concerns become more prominent, there’s a growing demand for environmentally friendly materials and processes. This necessitates exploring sustainable alternatives and minimizing the environmental footprint of Chemlok 205 production and application.

Emerging Trends in Materials Science

The field of materials science is constantly evolving, leading to new possibilities for enhancing Chemlok 205’s performance. Researchers are exploring novel polymeric structures and additives to improve the material’s resistance to various chemicals and physical stresses. Bio-based polymers are also being investigated as potential replacements for petroleum-based components, offering a more sustainable approach.

Potential Future Applications

Chemlok 205’s current applications span diverse industries. Future applications may include specialized coatings for infrastructure projects, such as bridges and tunnels, subjected to extreme weather conditions. Moreover, its potential in the aerospace and automotive industries, where lightweight yet robust materials are crucial, is worth exploring.

Improvements to Chemlok 205

Future research and development efforts could focus on enhancing Chemlok 205’s resistance to specific chemicals, increasing its durability, and reducing its environmental impact. This could involve incorporating bio-based additives or developing new polymerization techniques. The goal is to achieve a balance between performance and sustainability.

Ongoing Research and Development

Several research institutions and companies are actively investigating the potential of Chemlok 205. For instance, there’s growing interest in developing advanced formulations that can adapt to changing environmental conditions, such as temperature fluctuations and humidity. This adaptability could broaden the range of applications for the material. Specific research projects are focusing on the use of nanomaterials to enhance the material’s properties and improve its resistance to degradation.

Innovations in Manufacturing Processes

Optimizing manufacturing processes is crucial for the cost-effectiveness and scalability of Chemlok 205 production. Potential innovations include the implementation of more efficient polymerization techniques, reducing energy consumption during production, and developing automated systems for quality control. This is particularly relevant to increasing production volumes while maintaining high quality standards. Adopting 3D printing or other additive manufacturing techniques may be explored to create complex geometries or customized products.

Future of the Industry

The chemical industry is evolving rapidly, with increasing emphasis on sustainable practices and technological advancements. The future of the Chemlok 205 industry will depend on its ability to adapt to these changes. The growing demand for eco-friendly materials will likely drive innovation in formulations and manufacturing processes. Collaboration between research institutions, manufacturers, and end-users will be crucial in shaping the future of Chemlok 205 and its applications.

Concluding Remarks

Source: vecteezy.com

In conclusion, Chemlok 205 stands as a versatile and essential sealant, with a remarkable history and a promising future. From its diverse applications to its intricate manufacturing processes, this comprehensive guide has provided a thorough understanding of this critical product. By exploring its composition, performance, and safety considerations, this exploration has highlighted its significance across various industries and underscored its enduring importance in the field.