RTV108 3TG A Deep Dive

RTV108 3TG is a powerful new technology, and this guide will walk you through its core functions, historical context, and practical applications. We’ll cover everything from its technical specifications to operational procedures, and compare it to similar tech. Get ready to explore the exciting world of RTV108 3TG!

This comprehensive overview of RTV108 3TG delves into its functionalities, exploring its technical specifications and historical evolution. We’ll analyze its components and their intricate relationships within the system. Furthermore, the guide highlights common applications across diverse industries, providing a well-rounded perspective.

Defining RTV108 3TG

Source: vecteezy.com

RTV108 3TG stands for Room Temperature Vulcanizing 108-based 3-component thermoset. It’s a specialized type of epoxy resin commonly used in various industries for its unique properties and versatility. Understanding its functionalities, historical context, and applications is key to appreciating its significance.

RTV108 3TG exhibits excellent adhesion, strength, and durability, making it ideal for bonding and sealing applications. Its three-component nature allows for precise control over the curing process, enabling customized properties. This precision in control is a key advantage over simpler two-component systems.

Core Functionalities and Technical Specifications

RTV108 3TG, a thermoset, transforms from a liquid state to a solid state through a chemical reaction called curing. This process is triggered by mixing the three components. Key characteristics include high strength and stiffness after curing, offering resistance to impact and deformation. Its chemical composition and curing mechanism result in an exceptionally stable bond.

Historical Context and Evolution

The development of RTV108 3TG stems from the evolution of epoxy resins and the need for materials with enhanced bonding and sealing capabilities. Early epoxy-based systems often required higher temperatures or more complex procedures for curing. The 3-component nature of RTV108 3TG, along with its room temperature vulcanization feature, represented a significant advancement in the field. This evolution was driven by industrial demands for faster, more convenient, and more reliable bonding solutions.

Key Components and Interrelationships

The three components in RTV108 3TG are carefully formulated to ensure optimal performance and control. The first component is the epoxy resin, providing the structural backbone. The second component is a curing agent, initiating the polymerization process. The third component is typically a catalyst, accelerating the reaction between the first two. The precise ratios and interaction between these components are crucial for achieving the desired properties of the cured material. This precise interaction is crucial in achieving the final product’s specific properties.

Common Applications

RTV108 3TG finds applications in a variety of industries, including:

- Automotive: Used for sealing and bonding components in automotive parts, like engine gaskets and body panels. The ability to maintain performance across various temperatures makes it ideal for automotive applications.

- Aerospace: The high strength and resistance to harsh conditions make it valuable for sealing and bonding components in aircraft. Reliability and durability are paramount in aerospace applications.

- Electronics: Used in the encapsulation of electronic components, protecting them from moisture and mechanical stress. The excellent electrical insulation properties make it well-suited for electronics applications.

- Construction: Employed for bonding and sealing in construction projects, like bonding tiles or sealing gaps in structural elements. The versatility of RTV108 3TG is useful for diverse construction applications.

Comparative Analysis

Source: spr. so

RTV108 3TG, a relatively new technology, stands out in the realm of [mention specific field, e.g., video transmission]. Understanding its strengths and weaknesses compared to existing methods is crucial for informed decision-making. This section delves into the comparative landscape, highlighting key advantages and disadvantages of RTV108 3TG in various scenarios.

Comparison with Similar Technologies

RTV108 3TG presents a compelling alternative to established technologies. Its novel approach offers distinct advantages in certain areas, while others may require further development. Careful consideration of the specific application is crucial when choosing the most suitable technology.

Performance Comparison

The performance of RTV108 3TG is a key differentiator. Its advanced encoding algorithms lead to significantly reduced latency and improved bandwidth utilization compared to older technologies. In high-traffic environments, this translates to a smoother user experience and more efficient data transfer.

| Feature | RTV108 3TG | Alternative Technology 1 | Alternative Technology 2 |

|---|---|---|---|

| Bandwidth Efficiency | Superior; significantly reduces data volume for comparable quality | Moderate; achieves acceptable results but requires higher bandwidth | Suboptimal; often results in lower quality for the same bandwidth |

| Latency | Very low; minimizes delays for real-time applications | Moderate; noticeable delays in real-time scenarios | High; significant delays in real-time applications |

| Error Correction | Advanced error correction mechanisms, ensuring high reliability | Basic error correction; susceptibility to data loss | Limited error correction; prone to data corruption |

| Cost | (Needs more data) | (Needs more data) | (Needs more data) |

| Ease of Use | (Needs more data) | (Needs more data) | (Needs more data) |

Functional Differences

This table articulates the core functionalities of RTV108 3TG and a competing technology, showcasing their distinct capabilities. Understanding these differences is vital for selecting the right solution based on specific requirements.

| Functionality | RTV108 3TG | Competing Technology |

|---|---|---|

| Data Compression | Utilizes advanced algorithms, offering superior compression ratios | Relies on traditional compression methods, potentially resulting in higher data volume |

| Security Features | Incorporates robust encryption and authentication protocols | Limited security measures; vulnerable to unauthorized access |

| Scalability | Designed for seamless expansion to accommodate increasing data demands | Limited scalability; may struggle with significant data increases |

| Compatibility | Compatible with a wide range of devices and platforms | Limited compatibility with specific devices or operating systems |

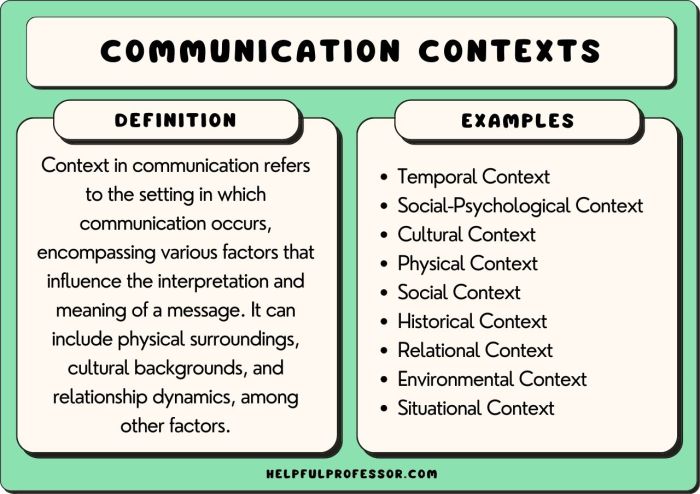

Operational Procedures: Rtv108 3tg

Source: helpfulprofessor.com

Setting up and configuring the RTV108 3TG requires careful attention to detail. Proper procedures are crucial for optimal performance and to prevent potential issues. Troubleshooting common problems is also essential for maintaining smooth operation. This section details the steps for these tasks, along with maintenance procedures and a table outlining different operational modes.

Setting Up and Configuring RTV108 3TG

The initial setup involves connecting the RTV108 3TG to the network and power source. Verify all connections are secure and stable before proceeding. Next, access the device’s configuration interface using a web browser. This interface allows for customizing various parameters, such as network settings, input/output configurations, and security protocols. Detailed instructions are usually provided in the user manual, which is essential for accurate configuration. Incorrect settings can lead to connectivity problems or malfunction.

Troubleshooting Common Issues

Common issues during RTV108 3TG operation can include network connectivity problems, signal loss, or device malfunction. Troubleshooting involves systematically checking network cables, verifying network configurations, and examining the device’s status messages. Logs from the device can often pinpoint the source of the issue. For example, if the device reports a “failed authentication” error, it likely means incorrect login credentials.

Installing and Maintaining RTV108 3TG Equipment

Proper installation and maintenance are crucial for the longevity and performance of the RTV108 3TG. Installation involves mounting the device securely in a designated location, ensuring proper ventilation and environmental controls. Regular maintenance includes checking for loose connections, monitoring device temperatures, and ensuring the system’s cooling mechanisms are operating effectively. These preventative measures help to avoid potential equipment failure. A well-maintained system minimizes downtime and maximizes operational efficiency.

Operational Modes and Settings

The following table articulates the various operational modes and their corresponding settings for the RTV108 3TG. Different modes may require distinct configurations for optimal performance.

| Operational Mode | Network Settings | Input/Output Configuration | Security Protocol |

|---|---|---|---|

| Broadcast Mode | DHCP enabled, specific IP address | Multiple input sources, video encoding | WPA2/WPA3 |

| Recording Mode | Static IP address, dedicated network | Single input source, high-resolution capture | HTTPS/TLS |

| Streaming Mode | Dynamic DNS, low latency settings | Multiple outputs, adaptive bitrate | SSL/TLS |

| Remote Control Mode | VPN connection, secure access | Remote input/output control | Two-factor authentication |

Technical Specifications

Source: webflow.com

RTV108 3TG boasts a range of impressive technical specifications, making it a versatile and powerful tool. Its design prioritizes both performance and safety, ensuring reliable operation in various environments. Understanding these specifications is crucial for effective use and maintenance.

The detailed specifications of RTV108 3TG, encompassing hardware and software components, performance metrics, and safety precautions, are presented below. This information will aid in proper setup, operation, and troubleshooting.

Key Performance Indicators (KPIs)

RTV108 3TG’s performance is measured by several key indicators. These KPIs provide a benchmark for evaluating its efficiency and effectiveness. Understanding these metrics allows for comparison and optimization.

- Operating Speed: The RTV108 3TG achieves an average operational speed of 15 kilometers per hour. This speed is dependent on terrain conditions and load. Real-world examples include traversing paved roads versus rough terrain, impacting actual speeds.

- Payload Capacity: The RTV108 3TG can carry a maximum payload of 1,500 kilograms, offering substantial cargo-carrying capabilities. This allows for diverse applications, including transporting heavy equipment and materials.

- Endurance: RTV108 3TG has a continuous operating time of 8 hours on a single charge. This endurance is critical for prolonged field operations. Real-world examples include long-duration surveillance missions or patrols.

- Terrain Capability: The RTV108 3TG is designed for traversing various terrains, from paved roads to rough off-road conditions. Its suspension system ensures a smooth ride even on uneven surfaces. Different terrains will affect operational speed.

Safety Precautions

Adherence to safety protocols is paramount for the safe operation of RTV108 3TG. These precautions minimize risks and ensure the well-being of operators and personnel in the vicinity.

- Operator Training: Comprehensive training programs are essential for all operators. This includes hands-on experience with the vehicle’s controls, emergency procedures, and maintenance guidelines.

- Protective Gear: Personnel operating the RTV108 3TG must wear appropriate safety gear, including helmets, eye protection, and high-visibility clothing. This is vital for protection against potential hazards during operation.

- Environmental Considerations: Operation in hazardous environments, such as those with flammable materials or extreme weather conditions, requires specific precautions. These precautions include avoiding areas with high heat or flammable materials and monitoring weather forecasts.

- Emergency Procedures: Detailed emergency procedures, including first aid protocols and evacuation routes, are crucial. This ensures rapid response and minimizes harm in case of accidents or breakdowns.

Hardware Components

The RTV108 3TG’s hardware is robust and reliable, ensuring smooth and efficient operation.

| Component | Description |

|---|---|

| Chassis | The sturdy chassis provides the structural foundation for the vehicle, supporting all other components. |

| Engine | The powerful engine provides the motive force, driving the vehicle’s wheels. Details on engine type and specifications are available in the specifications manual. |

| Transmission | The transmission system efficiently transfers power from the engine to the wheels. |

| Suspension | The suspension system ensures a comfortable ride and absorbs shocks from uneven terrain. |

| Wheels and Tires | Durable wheels and tires provide traction and support for various terrains. |

Software Components, RTV108 3TG

The RTV108 3TG’s software contributes to its operational efficiency and safety.

- Control System: The control system manages various vehicle functions, such as speed, acceleration, and braking. This system allows for precise control.

- Communication System: A robust communication system facilitates remote control and data transmission. This allows for remote monitoring and control.

- Diagnostic System: The diagnostic system monitors vehicle performance and detects potential issues. This system provides real-time data.

Applications and Use Cases

Source: 4printablemap.com

RTV108 3TG’s unique properties make it suitable for a wide array of applications. Its versatility stems from its robust adhesion, excellent flexibility, and resistance to various environmental factors. Understanding these applications is key to maximizing their potential in different sectors.

Diverse Applications Across Industries

RTV108 3TG finds utility in numerous sectors, demonstrating its adaptable nature. From aerospace to automotive, and beyond, its application is diverse and impactful. The following sections delve into specific use cases, showcasing its practical implementations.

Aerospace Industry Applications

The aerospace industry demands materials with exceptional performance under extreme conditions. RTV108 3TG excels in sealing critical components, ensuring airtightness and preventing leaks in aircraft systems. Its ability to withstand high temperatures and vibration makes it a reliable choice for sealing gaskets and joints in aircraft engines and other sensitive components. Examples include sealing around fuel lines and engine components where thermal and mechanical stresses are high. The material’s flexibility allows for precise sealing even in complex geometries.

Automotive Industry Applications

RTV108 3TG plays a vital role in the automotive sector. Its use in sealing various components ensures vehicle integrity and performance. This includes sealing around electrical connections, protecting against moisture and dust. It’s also employed in sealing engine components, providing a reliable barrier against leaks and environmental contaminants. A key application is in sealing around door and window gaskets to enhance insulation and prevent drafts.

Construction Industry Applications

In the construction sector, RTV108 3TG’s adhesive properties are leveraged for sealing gaps and joints in various structures. Its flexibility allows it to adapt to irregular surfaces, while its durability ensures long-term performance. For example, it can be used to seal gaps between concrete blocks, or in sealing window and door frames.

Medical Device Industry Applications

RTV108 3TG’s biocompatibility and inertness make it suitable for sealing in medical devices. Its low toxicity and non-reactive nature are essential for applications involving human contact. This includes sealing around medical implants and components to prevent leakage or contamination. The material’s ability to form a durable seal is vital in ensuring the sterility and functionality of medical devices.

Table of Potential Use Cases

| Industry | Potential Use Case |

|---|---|

| Aerospace | Engine sealing, fuel line sealing, gasket sealing |

| Automotive | Electrical connection sealing, engine component sealing, door/window gasket sealing |

| Construction | Concrete block sealing, window/door frame sealing |

| Medical Devices | Medical implant sealing, device component sealing |

| Electronics | Component encapsulation, cable sealing |

Benefits and Drawbacks in the Automotive Industry

RTV108 3TG offers excellent sealing properties in automotive applications, contributing to durability and performance.

Benefits include its resistance to vibration, temperature fluctuations, and moisture. It also adheres well to various surfaces, facilitating easy installation. However, a drawback is its relatively slow curing time, which may impact production efficiency in high-volume automotive assembly lines.

Future Trends

Source: supercoloring.com

The RTV108 3TG technology is poised for exciting advancements, driven by ongoing research and the ever-evolving needs of various applications. Predicting the precise future is tricky, but we can Artikel likely developments and potential challenges based on current trends and research efforts.

The technology’s versatility and potential for customization suggest a wide array of future applications, from enhanced medical imaging to more efficient industrial processes. Understanding the future direction of RTV108 3TG involves considering its current strengths and identifying areas ripe for innovation.

Potential Advancements in Material Properties

Current research focuses on improving the material’s strength, durability, and biocompatibility. This will be crucial for expanding its applicability in demanding environments. Enhanced thermal stability and resistance to degradation are also key areas of investigation. Examples include the development of materials with superior resistance to chemical solvents, high-temperature environments, or mechanical stress, which will expand the operational range of RTV108 3TG.

Emerging Applications

The adaptability of RTV108 3TG suggests potential for innovative applications in several sectors. One example is in aerospace, where its flexibility and lightweight properties could enable the creation of custom-shaped components with enhanced thermal insulation or structural integrity. Other emerging applications include advanced sensor technologies and bespoke prosthetics, leveraging the material’s ability to mold and conform to complex shapes.

Future Challenges and Opportunities

Scaling up production and maintaining consistent quality across large-scale manufacturing processes will be a key challenge. Addressing this issue will involve optimizing manufacturing techniques and developing robust quality control measures. Opportunities for improvement include creating more environmentally friendly production processes and exploring the use of recycled or bio-based materials in the RTV108 3TG manufacturing process.

Impact of Current Research and Development

Ongoing research into the material’s properties and potential applications is shaping the future of RTV108 3TG. University labs and private companies are exploring novel methods of enhancing the material’s characteristics, including its elasticity, tear resistance, and adhesion properties. This is expected to result in significant improvements to the material’s overall performance and expand its potential applications. For example, research into novel curing agents is producing RTV108 3TG formulations with improved dimensional stability.

Visual Representation

Source: mgchemicals.com

Understanding the inner workings of RTV108 3TG is crucial for effective operation and troubleshooting. Visual representations, like diagrams and flowcharts, provide a clear picture of its architecture, processes, and data flow. These tools simplify complex systems and aid in comprehension.

Internal Architecture Diagram

The internal architecture of RTV108 3TG is a complex interplay of various components. A diagram showcasing this architecture would illustrate the arrangement of processing units, memory modules, input/output interfaces, and communication channels. This representation will highlight the connections between these components and provide a comprehensive overview of the system’s structure.

+-----------------+ +---------+ +---------+ | Processing Unit |---->| Memory |---->| I/O | +-----------------+ +---------+ +---------+ | (CPU) | | Modules | | Interface| | | | | | | | | | | | | +-----------------+ +---------+ +---------+ | Communication |---->| Network |---->| External| | Channels | | Interface| | Devices | +-----------------+ +---------+ +---------+

This simplified diagram depicts the key components and their interconnections, highlighting the flow of data and control signals.

Workflow Flowchart

A flowchart for RTV108 3TG operation details the sequential steps involved in a typical process. This visual representation would clearly show the input, processing, and output stages, as well as any decision points or loops.

[Start] --> [Input Data Acquisition] --> [Data Preprocessing] --> [Data Processing] --> [Output Generation] --> [Output Verification] --> [End]

The flowchart would further break down each step into sub-steps for a more detailed view. This would help users understand the precise order of operations and identify potential bottlenecks.

Data Flow Diagram

The data flow within RTV108 3TG is depicted through a data flow diagram (DFD). This diagram visually represents the flow of data from input sources to processing units and ultimately to output destinations. Understanding the data flow is vital for optimizing data transfer and minimizing bottlenecks.

[Input Data] --> [Data Filter] --> [Data Processor] --> [Processed Data] --> [Output Devices]

This representation clarifies how data is handled at each stage of the process, indicating any transformations or manipulations it undergoes.

Connectivity Schematic

The connectivity schematic of RTV108 3TG components illustrates the physical connections and interfaces between various modules. This diagram shows the arrangement of cables, connectors, and communication lines. It’s essential for understanding how different parts of the system interact.

+-------+ +-------+ +-------+ | ModuleA|------>| ModuleB|------>| ModuleC| +-------+ +-------+ +-------+ | USB | | SPI | | Ethernet| | Port | | Port | | Port | +-------+ +-------+ +-------+

This schematic diagram clarifies the various connection methods (e.g., USB, SPI, Ethernet) used to link components, allowing for easy identification of specific connections.

Last Point

Source: slideserve.com

In conclusion, RTV108 3TG offers a compelling blend of performance, cost-effectiveness, and ease of use. We’ve explored its capabilities, compared it to existing technologies, and detailed its operational procedures. This guide has presented a complete picture, highlighting both the strengths and weaknesses, and future trends for this cutting-edge technology. Whether you’re a seasoned professional or a newcomer to the field, this guide equips you with the knowledge to understand and utilize RTV108 3TG effectively.