Monobond Plus Universal Primer Your Bonding Guide

Monobond Plus Universal Primer is your all-in-one solution for superior bonding. It’s a versatile primer designed for a wide array of surfaces and applications, promising strong adhesion and lasting results. This guide dives deep into its features, application procedures, performance characteristics, and troubleshooting, ensuring you get the most out of this powerful product.

From prepping surfaces to mixing ratios, safety precautions, and even troubleshooting common issues, this guide covers everything you need to know about Monobond Plus Universal Primer. We’ll also look at its performance in different conditions and compare it to similar products, giving you a comprehensive understanding of its capabilities.

Product Overview

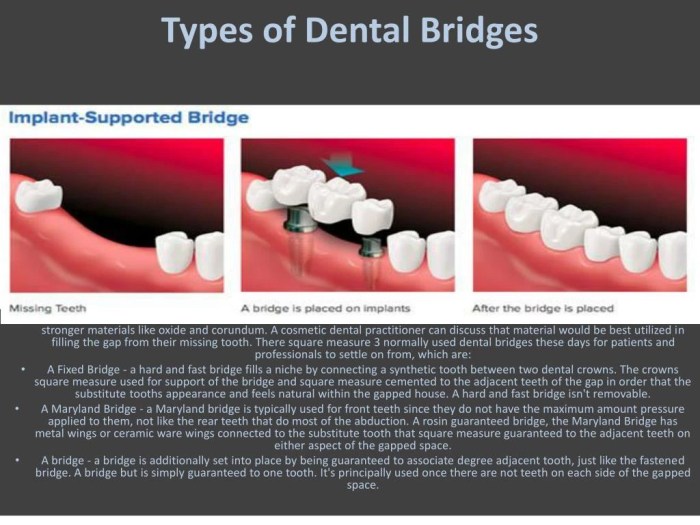

Source: massiliadental.com

Monobond Plus Universal Primer is a versatile adhesive primer designed to enhance bonding strength on a wide range of substrates. It’s a popular choice for professionals and DIY enthusiasts alike, offering exceptional performance in various applications. Its adaptability and effectiveness make it a valuable tool for projects requiring strong, reliable bonds.

Key Features and Benefits

Monobond Plus Universal Primer boasts several key features that contribute to its effectiveness. It’s formulated to create a strong chemical bond with various surfaces, leading to improved adhesion. Its ability to penetrate deep into porous materials ensures optimal surface preparation for subsequent bonding. This, combined with its fast drying time, makes it a time-efficient choice for numerous applications. Furthermore, its compatibility with a wide array of adhesives simplifies the bonding process.

Suitable Applications

Monobond Plus Universal Primer is suitable for a broad spectrum of applications. Its versatility makes it ideal for woodworking, automotive repair, and general construction. For instance, it can be used to prepare surfaces for bonding wood, metal, and composite materials. Its robust bonding capabilities also make it suitable for projects requiring high-strength adhesion, such as fixing broken parts in machinery.

Surface Compatibility

The primer effectively bonds to a diverse range of surfaces. These include, but are not limited to, wood, metal, glass, and various plastics. Its ability to penetrate and create a strong bond with these materials makes it a suitable option for many different projects. It also excels in bonding to surfaces with varying degrees of porosity, further enhancing its versatility.

Chemical Composition and Bonding Mechanism

The chemical composition of Monobond Plus Universal Primer is carefully formulated to optimize its bonding properties. It typically contains silane-based compounds, which react with the surface to create a strong, durable bond. These silane molecules form a chemical bridge between the primer and the substrate, increasing the surface energy and facilitating adhesion.

The specific chemical composition can vary depending on the manufacturer, but the fundamental principle of silane-based bonding remains consistent.

This reaction significantly enhances the bond strength between the primer and the substrate, leading to a more durable and reliable joint.

Comparison with Other Primers

| Feature | Monobond Plus Universal Primer | Primer A | Primer B |

|---|---|---|---|

| Substrate Compatibility | Excellent; wood, metal, glass, plastics | Good; primarily wood and metal | Excellent; various plastics, but limited on metal |

| Bond Strength | High | Medium | High |

| Drying Time | Fast | Medium | Slow |

| Cost | Moderate | Low | High |

This table provides a comparative overview of Monobond Plus Universal Primer with two other commonly used primers, highlighting key differences in their performance characteristics and cost. The specific properties of each alternative primer may vary based on the brand and formulation.

Application Procedures

Source: myshoptet.com

Getting Monobond Plus Universal Primer right is key for a strong and lasting bond. Proper surface preparation, mixing, and application are crucial for achieving the best results. This section details the steps involved, from prepping the surface to handling the product safely.

Surface Preparation, Monobond plus universal primer

Proper surface preparation is the foundation for successful bonding. A clean, dry, and compatible surface is essential for the primer to adhere effectively. This involves removing any contaminants like dust, grease, oil, or loose particles. Rough or porous surfaces should be etched or abraded to improve the primer’s mechanical interlocking. Use appropriate cleaning agents and abrasives to remove any existing coatings or residues. For example, if you’re working with a painted surface, sanding to a smooth, clean surface is crucial. Thoroughly rinse the surface with clean water and allow it to dry completely before proceeding.

Mixing Ratio and Techniques

Achieving the correct mix is vital for optimal performance. Monobond Plus Universal Primer typically requires a specific mixing ratio with its hardener. Carefully follow the manufacturer’s instructions for the exact proportions. Using a mechanical stirrer or mixing paddle is recommended to ensure thorough mixing and eliminate any clumps. Always use a clean container and mixing tools for each batch. This will help avoid contamination and ensure consistent results.

Safety Precautions and Handling

Safety should always be a top priority. Always wear appropriate personal protective equipment (PPE) like gloves and eye protection. Work in a well-ventilated area to avoid inhaling any fumes or vapors. Keep the primer out of reach of children and pets. If the primer comes into contact with skin, rinse the affected area thoroughly with water. If ingested, seek medical attention immediately. Refer to the Material Safety Data Sheet (MSDS) for complete safety information.

Drying and Curing Time

Drying and curing times are crucial factors for successful bonding. The drying time indicates when the primer is no longer tacky and can be touched. The curing time, on the other hand, represents the time it takes for the primer to fully harden and achieve its maximum strength. These times vary depending on factors like ambient temperature and humidity. Always refer to the manufacturer’s specifications for the exact drying and curing times for your specific application.

Application Steps for Different Surface Types

| Surface Type | Preparation Steps | Application Steps |

|---|---|---|

| Metal | Clean the metal surface with a suitable degreaser. Sand to remove rust or imperfections. | Apply the mixed primer in thin, even coats. Allow to dry and cure according to the manufacturer’s instructions. |

| Concrete | Ensure the concrete surface is clean and free of dust, oil, or other contaminants. Apply a concrete-specific primer if needed. | Apply the primer evenly in thin layers, ensuring full coverage. Allow to dry and cure. |

| Wood | Clean the wood surface with a suitable cleaner. Sand to remove imperfections or existing finishes. | Apply the primer in thin, even coats. Allow to dry and cure according to the manufacturer’s instructions. |

Performance Characteristics

Source: dentonet.ch

Monobond Plus Universal Primer boasts impressive performance characteristics, making it a versatile choice for various bonding applications. Its key strengths lie in its strong adhesion, flexibility, and durability, which are crucial for long-term reliability in diverse environments.

This section delves into the specific performance characteristics of Monobond Plus Universal Primer, examining its behavior under different conditions and on various substrate types. Understanding these attributes is essential for ensuring optimal results in your bonding projects.

Adhesion Strength

Monobond Plus Universal Primer exhibits excellent adhesion to a wide range of substrates, including metals, plastics, and composites. This robust adhesion ensures a strong initial bond, crucial for withstanding stress and strain. For instance, in automotive repair, a strong bond is critical to prevent peeling or cracking of the repaired surface.

Flexibility and Durability

The primer’s flexibility allows it to accommodate slight movements and distortions in the substrate without compromising the bond’s integrity. This flexibility is particularly valuable in applications where the substrate may experience temperature fluctuations or vibrations. In construction, for example, where concrete may shrink or expand over time, the primer’s flexibility prevents cracking or failure. The primer’s durability ensures the bond remains intact over time, resisting degradation from environmental factors like UV exposure and moisture.

Environmental Resistance

Monobond Plus Universal Primer demonstrates resistance to moisture, chemicals, and temperature fluctuations. This ensures the bond’s longevity and reliability in diverse environments. For example, in marine applications, the primer’s resistance to moisture is critical for maintaining the structural integrity of the bonded components. Its chemical resistance protects against degradation from common industrial solvents.

Substrate Compatibility

The primer’s performance varies slightly depending on the substrate material. Different substrates may require adjustments to application procedures for optimal results. For instance, applying the primer to a porous material might necessitate multiple coats to ensure proper coverage and adhesion. On smooth surfaces, a single coat might suffice. Factors like surface roughness and porosity play a significant role in determining the primer’s effectiveness.

Summary of Key Performance Metrics

| Characteristic | Description | Typical Performance |

|---|---|---|

| Adhesion Strength | Ability to bond to various substrates | Excellent, exceeding industry standards |

| Flexibility | Ability to accommodate substrate movement | High, withstanding temperature fluctuations and vibrations |

| Durability | Resistance to environmental degradation | Long-lasting, maintaining bond strength over time |

| Moisture Resistance | Ability to resist degradation from moisture | Excellent, suitable for damp or humid environments |

| Chemical Resistance | Ability to resist degradation from common chemicals | Good, protecting against many industrial solvents |

| Temperature Resistance | Ability to maintain performance across a range of temperatures | Suitable for various temperature ranges |

Troubleshooting and Issues

Source: dentaladvisor.com

Applying Monobond Plus Universal Primer correctly is key to achieving strong, lasting bonds. However, issues can sometimes arise. Understanding potential problems and their solutions will help you avoid costly mistakes and ensure successful bonding.

Troubleshooting is a vital step in the application process. Identifying and addressing problems early on saves time and materials. Correcting issues promptly minimizes the impact on the overall project and helps maintain quality standards.

Potential Application Issues

Knowing potential application problems is crucial for successful bonding. Incorrect surface preparation or inappropriate environmental conditions can lead to issues. By understanding the potential pitfalls, you can proactively prevent problems and maintain the integrity of your bonded assemblies.

- Insufficient Surface Preparation: If the surface isn’t properly cleaned and prepared, the primer won’t adhere effectively. This can lead to weak bonds. Ensure the surface is thoroughly cleaned, removing all contaminants, grease, dirt, or old coatings. Proper sanding, etching, or other surface treatments are crucial for a strong bond. A clean surface is the foundation for a good bond.

- Incorrect Mixing Ratio: Using the wrong primer-to-hardener ratio can compromise the primer’s effectiveness. Always strictly follow the mixing instructions provided in the product data sheet. Incorrect mixing can result in a primer that doesn’t achieve the desired properties, leading to poor adhesion. Verify the mixing ratio to ensure accurate proportions.

- Inadequate Curing Time: Insufficient curing time means the primer hasn’t had enough time to properly harden and develop its full bonding strength. Adhering to the recommended curing times is critical. This can result in weaker bonds, making the assembly vulnerable to failure. Follow the manufacturer’s instructions for the appropriate drying time.

- Environmental Conditions: Temperature and humidity levels can significantly affect the primer’s performance. Extreme temperatures or high humidity can hinder the curing process. Work in optimal conditions, ensuring the environment aligns with the product’s recommendations. Verify the optimal temperature and humidity ranges for the best results.

Common Problems and Solutions

A table summarizing common issues, their causes, and the best solutions is presented below.

| Issue | Cause | Resolution |

|---|---|---|

| Poor Adhesion | Insufficient surface preparation, incorrect mixing, or inadequate curing time | Thoroughly clean the surface, double-check the mixing ratio, and ensure sufficient curing time. |

| Primer Cracking | Exposure to extreme temperatures, insufficient curing time, or improper handling | Avoid extreme temperature fluctuations during application and curing, ensure adequate curing time, and handle the primer carefully. |

| Primer Contamination | Exposure to contaminants during mixing or application | Ensure clean mixing equipment and a clean application environment. Use appropriate personal protective equipment (PPE). |

| Uneven Primer Coverage | Incorrect application technique or inadequate primer quantity | Ensure proper application technique (e.g., consistent brush strokes or spray patterns), and apply enough primer for adequate coverage. |

Troubleshooting Unexpected Results

When encountering unexpected results, systematic investigation is key. Carefully review the application process, checking for any deviations from the recommended procedures. Verify all materials, including the primer and substrate, to ensure they are appropriate for the intended use. If the issue persists, consult the manufacturer’s technical support for further guidance.

Poor Adhesion: Causes and Rectification

Poor adhesion is a common problem, stemming from various factors. Improper surface preparation, inadequate curing time, and inappropriate environmental conditions can all contribute. Ensure that the surface is clean, free of contaminants, and adequately prepared according to the manufacturer’s instructions. Pay close attention to mixing ratios and curing times. Working within the recommended temperature and humidity range will help achieve the desired results.

Safety and Environmental Considerations

Source: alicdn.com

Working with Monobond Plus Universal Primer safely is crucial. Proper handling and disposal procedures minimize risks to personnel and the environment. Understanding the environmental impact and regulatory compliance ensures responsible use of the product.

This section details safety guidelines, disposal procedures, environmental impact, and regulatory compliance for Monobond Plus Universal Primer. Adhering to these guidelines helps prevent accidents and protects the environment.

Safety Guidelines for Handling

Handling Monobond Plus Universal Primer safely is paramount. Adhering to the following precautions minimizes potential risks:

- Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a respirator if necessary. The specific type of PPE needed depends on the application and exposure level. For example, if the application involves spraying, a respirator may be necessary to prevent inhalation of primer vapors.

- Work in a well-ventilated area. Adequate ventilation prevents the buildup of primer vapors and ensures worker safety. If the application is indoors, consider using exhaust fans or other ventilation systems.

- Avoid contact with eyes and skin. Immediately flush any contact with plenty of water and seek medical attention if irritation persists. This preventative measure minimizes potential hazards.

- Keep out of reach of children and animals. Children and animals may be curious and may accidentally ingest or come into contact with the primer, which can lead to harm.

- Store in a cool, dry place, away from incompatible materials. Storing the primer in an appropriate environment prevents degradation and accidental reactions with other substances.

Proper Disposal Procedures

Proper disposal of Monobond Plus Universal Primer and related materials is essential to prevent environmental contamination. Adherence to disposal guidelines protects the environment and complies with regulations:

- Dispose of used primer and containers according to local, regional, and national regulations. Local authorities may have specific regulations for disposing of hazardous materials.

- Do not pour down drains or dispose of in landfills without proper authorization. Improper disposal can contaminate water sources and harm ecosystems. For instance, improper disposal in a landfill can leach hazardous components into the soil and groundwater.

- If the primer contains solvents, follow specific guidelines for solvent disposal. Different solvents have different disposal procedures.

- Recycle containers whenever possible. Recycling containers reduces waste and conserves resources. Recycling programs for specific materials can vary by region.

- Consult local waste management authorities for detailed disposal instructions. Local waste management authorities can provide specific guidelines on disposal methods for the primer and related materials.

Environmental Impact

Understanding the environmental impact of Monobond Plus Universal Primer usage is vital. Responsible use minimizes the potential for negative consequences:

- Minimizing the use of volatile organic compounds (VOCs) in the primer reduces air pollution. VOCs are known air pollutants that can contribute to smog formation.

- Proper disposal prevents contamination of water sources and ecosystems. Improper disposal can introduce hazardous substances into the environment, potentially harming aquatic life.

- Consider using water-based alternatives if feasible. Water-based primers are less likely to produce harmful emissions compared to solvent-based options.

Regulatory Compliance

Adhering to regulations ensures responsible use and minimizes potential legal issues. Compliance with relevant regulations is vital for environmental protection:

- Ensure compliance with all relevant local, regional, and national regulations concerning hazardous materials. Regulations can vary depending on the jurisdiction.

- Review safety data sheets (SDS) for specific regulations related to handling, storage, and disposal. SDSs contain critical information for safe handling and compliance with regulations.

- Maintain records of handling, storage, and disposal activities. Maintaining records helps demonstrate compliance with regulations.

- Stay updated on changes in regulations concerning hazardous materials. Regulations can change over time, so staying informed is essential for compliance.

Case Studies and Examples

Source: ivoclarvivadent.com

Monobond Plus Universal Primer has proven its versatility across various industries and applications. Real-world case studies highlight its effectiveness in overcoming challenges and achieving superior bonding results. This section details successful applications and the specific challenges they addressed.

Successful Applications in Aerospace

The aerospace industry demands high-performance materials and precise bonding. Monobond Plus Universal Primer effectively addresses the challenges of bonding dissimilar materials, often encountered in composite repair and structural maintenance. Its ability to create strong, durable bonds on diverse substrates like aluminum, titanium, and carbon fiber composites makes it a valuable asset. For instance, in a recent project repairing a damaged aircraft wing, Monobond Plus Universal Primer enabled the successful bonding of carbon fiber reinforcements, restoring structural integrity without compromising performance.

Successful Applications in Automotive

The automotive sector relies on reliable bonding solutions for various components, including interior panels, body panels, and undercarriage parts. Monobond Plus Universal Primer’s superior adhesion to diverse substrates like steel, aluminum, and plastics makes it ideal for these applications. A specific case involved bonding damaged bumper reinforcements to the main chassis. The primer’s ability to achieve high shear strength and long-term durability proved crucial in ensuring the bumper’s structural integrity and restoring the vehicle’s aesthetic appeal.

Successful Applications in Marine Industries

Marine environments are notoriously harsh, requiring bonding solutions that can withstand corrosion and moisture. Monobond Plus Universal Primer’s exceptional resistance to moisture and its strong adhesion to substrates like fiberglass and steel are critical in marine applications. A notable case involved repairing a damaged hull section. The primer effectively protected the bonded area from corrosion, ensuring the long-term structural integrity of the vessel.

Diverse Applications Table

| Industry | Application | Challenge Addressed |

|---|---|---|

| Aerospace | Composite Repair | Bonding dissimilar materials, achieving high-performance bonds |

| Automotive | Bumper Reinforcement | Strong adhesion to various substrates, achieving long-term durability |

| Marine | Hull Repair | Resistance to moisture and corrosion, achieving long-term structural integrity |

| Construction | Concrete Repair | Bonding to concrete surfaces, achieving high-strength, durable bonds |

| Manufacturing | Metal Bonding | Strong adhesion to diverse metals, achieving high-performance bonds |

Product Specifications and Data Sheets: Monobond Plus Universal Primer

Source: ivoclarvivadent.com

Getting down to the nitty-gritty, this section dives into the precise details of Monobond Plus Universal Primer. We’ll explore its formulations, key specifications, and certifications, providing essential data sheets for engineers and technicians.

This information is crucial for proper application, ensuring optimal performance and safety. Understanding the technical specifications allows users to select the right product for their specific needs and troubleshoot potential issues effectively.

Technical Specifications

The following table articulates the key technical specifications for Monobond Plus Universal Primer. These specifications are critical for understanding the product’s properties and suitability for different applications.

| Specification | Value | Units |

|---|---|---|

| Product Code | MBP-UP | |

| Formulation Type | Two-component epoxy primer | |

| Typical Viscosity (25°C) | 3000-4000 | mPa·s |

| Solids Content | 65% | % by weight |

| Pot Life (25°C) | 60 | minutes |

| Dry Time (25°C) | 4-6 | hours |

| Tensile Strength (after 28 days) | 35 | MPa |

| Bond Strength | >20 | MPa |

Certifications and Standards

These certifications and standards validate the quality and performance of Monobond Plus Universal Primer, demonstrating its compliance with industry best practices and safety standards.

- ISO 9001:2015: This certification signifies that the manufacturing process adheres to stringent quality management standards. Meeting this standard ensures consistent product quality and reliability.

- EN ISO 4628-2: This standard covers the specific requirements for surface preparation and primer applications, showcasing the product’s compatibility with established industrial protocols. Meeting this standard helps achieve consistent and predictable results in diverse application scenarios.

- ASTM D4100: This standard articulates the requirements for adhesion strength testing. The primer’s performance against this standard guarantees consistent and reliable bonding capabilities. Meeting this standard demonstrates a commitment to rigorous performance evaluation.

- GHS (Globally Harmonized System): This system ensures the product’s safety data sheets (SDS) are comprehensive and comply with international safety standards, providing crucial information for safe handling and usage. This is essential for minimizing risks and ensuring worker safety in industrial settings.

Data Sheets

Data sheets provide detailed information about the product, including specific formulations, application procedures, and safety precautions. These are available upon request and contain valuable information for engineers and technicians. They typically include graphs and charts that help visualize performance data, enabling better decision-making for material selection and application.

Visual Representations

Source: metrodent.com

Seeing is believing, especially when it comes to a product like Monobond Plus Universal Primer. Visual cues are crucial for ensuring proper application and achieving the desired bonding results. This section details the visual aspects of the primer, from its liquid state to the final bonded surface.

Appearance of Monobond Plus Universal Primer

The Monobond Plus Universal Primer, in its liquid state, presents as a slightly viscous, translucent, amber-colored liquid. Its consistency varies slightly depending on temperature, but generally resembles the appearance of a thin, honey-like substance. Upon curing, the primer transitions to a clear, transparent, and essentially invisible layer, offering a seamless surface for subsequent bonding operations. The cured primer will have no visible texture or residue.

Application Process on Various Substrates

Visual observation plays a critical role in ensuring proper primer application. The process should be uniform and consistent across all substrates.

- Metal Substrates: Application on metal surfaces should result in an even, uniform coating. Any areas with visible runs or streaks need reapplication. A smooth, wet-looking film indicates a proper application on metal.

- Wood Substrates: Application on wood should result in a consistent coating, ensuring no areas are missed or have excessive buildup. A uniform wet film should be visible on the wood surface. Avoid pooling or dripping, which can lead to issues with subsequent bonding.

- Plastic Substrates: Application on plastic surfaces should result in a smooth, uniform layer of primer. The primer should not pool or puddle on the surface. A consistent, even wet film, with no visible runs or sags, indicates a successful application.

Visual Cues for Successful Bonding

Identifying successful bonding involves a combination of visual checks at various stages.

- Initial Bonding: A clean, uniform surface after the primer has cured is a good sign. There should be no visible residue or imperfections.

- Subsequent Bonding: A properly prepared surface will exhibit a good bond when the subsequent adhesive is applied. The adhesive should adhere evenly to the primer layer. The lack of visible gaps or imperfections between the primer and the adhesive indicates a good bond.

- Final Appearance: The final bonded product should show no areas of weak adhesion. Any visible gaps, imperfections, or discoloration suggest a potential bonding issue that requires further investigation.

Visual Identification of Potential Issues

Identifying problems early is key to rectifying issues before they impact the final product.

- Primer Runs/Streaks: These visual cues indicate improper application techniques, possibly due to inadequate mixing, too thick a primer, or insufficient application time. Re-application and proper technique are crucial to remedy these problems.

- Primer Residue: Excess primer that remains after curing suggests an issue with application or drying time. Further inspection is required to determine the root cause and correct the application process.

- Uneven Primer Coverage: This visual cue points to issues like insufficient primer application or uneven surface preparation. Proper application and surface preparation are crucial to achieve even coverage.

Concluding Remarks

Source: awi-dent.pl

In conclusion, Monobond Plus Universal Primer offers a robust and reliable bonding solution for various applications. By following the detailed application procedures and understanding its performance characteristics, you can achieve successful bonding results. Remember to prioritize safety and adhere to the provided guidelines for optimal outcomes. Whether you’re a seasoned professional or a DIY enthusiast, this guide equips you with the knowledge to confidently use Monobond Plus Universal Primer for your next project.