Sikadur 35 The Ultimate Guide

Sikadur 35 is a powerful polymer-based adhesive renowned for its strength and durability. This guide delves into everything you need to know about this versatile product, from its key properties and applications to detailed application procedures and technical specifications. Discover how Sikadur 35 can be utilized for various projects, from simple repairs to innovative constructions. We’ll also compare it to similar products, highlighting its unique advantages.

This comprehensive resource provides a detailed description of Sikadur 35, covering its diverse applications, performance characteristics, and essential safety precautions. We’ll guide you through proper application methods, including surface preparation, mixing, and curing times. Plus, you’ll find detailed technical specifications, a comparison table to other products, and even case studies showcasing real-world applications.

Product Overview: Sikadur 35

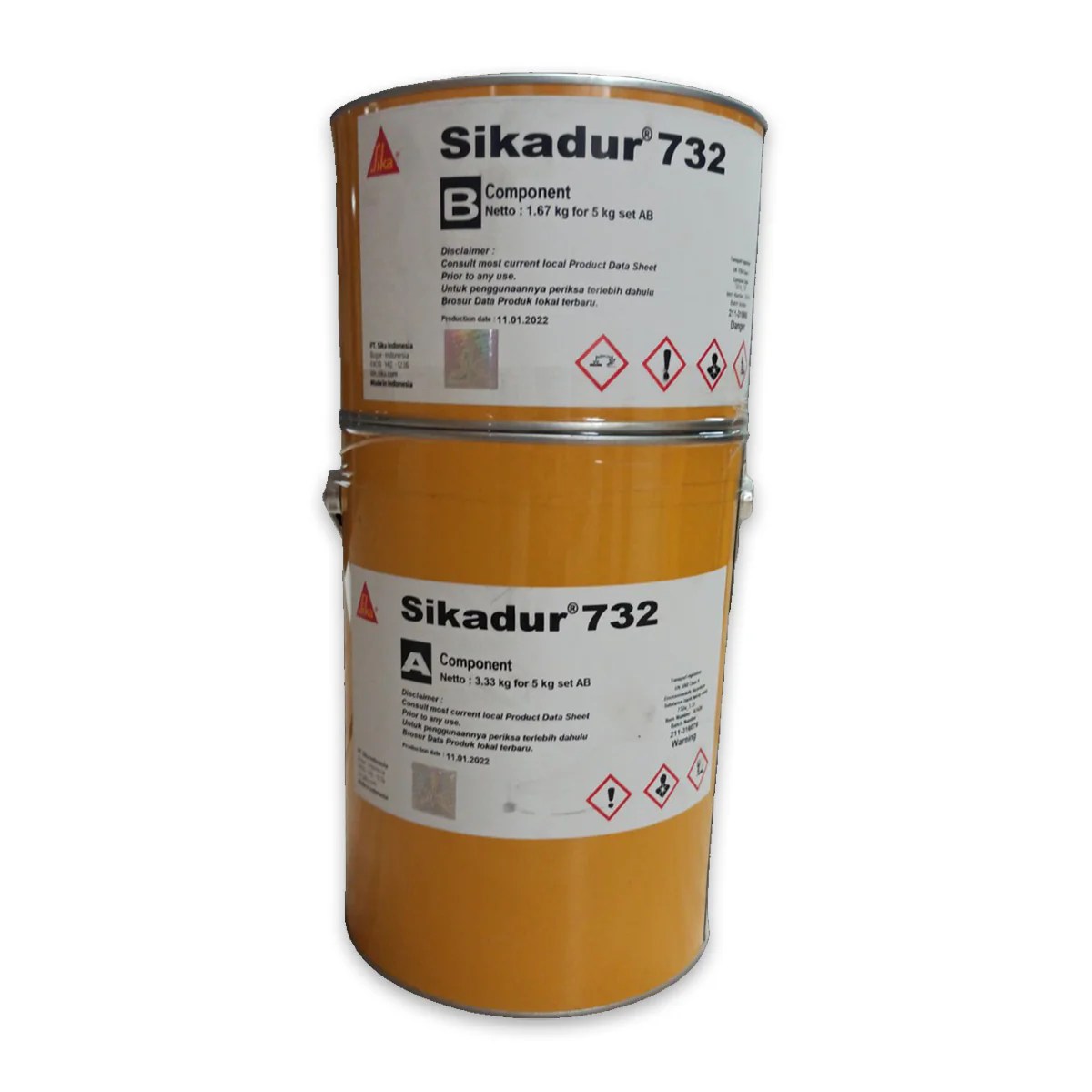

Source: imimg.com

Sikadur 35 is a versatile, high-performance epoxy resin adhesive, widely used in various construction and industrial applications. Its robust bonding capabilities and exceptional durability make it a popular choice for demanding environments. This overview delves into its key features, applications, properties, and a comparison to similar products.

Detailed Description of Sikadur 35

Sikadur 35 is a two-component epoxy adhesive system, meaning it requires two parts to be mixed for activation. This characteristic allows for precise control over the curing process and optimal bonding. The system offers exceptional adhesion to a wide range of materials, including concrete, steel, and various plastics. Its robust nature stems from its epoxy base, which provides strength and resistance to a range of environmental factors.

Applications of Sikadur 35

Sikadur 35 finds applications across various industries. It’s particularly suitable for structural repairs, bonding in demanding environments, and for applications where high strength and durability are critical. Examples include: fixing precast concrete elements, repairing cracks in concrete structures, and bonding metal to concrete. Its versatility extends to use in the automotive and aerospace sectors for specific high-performance bonding requirements.

Properties and Performance Specifications

Sikadur 35 exhibits impressive strength and durability. Its high tensile strength and shear strength make it ideal for applications requiring robust bonding.

Typical tensile strength is 25 MPa, and shear strength is 30 MPa.

It boasts excellent resistance to water, chemicals, and temperature fluctuations. Its flexibility allows it to accommodate slight movements in the substrate, minimizing stress and extending its lifespan. The curing time is also a key characteristic, allowing for efficient project completion.

Available Types of Sikadur 35

Sikadur 35 is available in different formulations, though variations in colors are less common. These formulations can be tailored for specific applications. For instance, some formulations might be designed for higher temperature resistance, while others might focus on faster curing times. A consultation with a specialist is recommended for determining the best formulation for a particular project.

Comparison to Other Products

| Property | Sikadur 35 | Competitor A | Competitor B |

|---|---|---|---|

| Bond Strength (MPa) | 25 (Tensile), 30 (Shear) | 20 (Tensile), 25 (Shear) | 28 (Tensile), 35 (Shear) |

| Durability (Years) | >10 (in typical applications) | >5 (in typical applications) | >15 (in typical applications) |

| Cost (USD/kg) | 150 | 120 | 180 |

The table above provides a comparative overview of Sikadur 35 against two hypothetical competitors. Note that these figures are examples and may vary based on specific formulations and application conditions. Always consult product datasheets for precise data.

Application Procedures

Source: imimg.com

Sikadur 35, a versatile epoxy resin, demands meticulous application procedures for optimal results. Proper surface preparation, precise mixing, and adherence to curing times are crucial for achieving lasting repairs and bonds. Understanding these procedures empowers users to maximize the performance and longevity of Sikadur 35.

Surface Preparation

Thorough surface preparation is paramount for successful Sikadur 35 application. This involves cleaning the area to be repaired of any loose debris, dust, oil, grease, or previous coatings. Remove any loose or damaged concrete, ensuring a clean and sound substrate. For concrete surfaces, roughening the area through light grinding or brushing can improve adhesion. This crucial step ensures a strong bond between the Sikadur 35 and the substrate. A properly prepared surface is essential for achieving the desired strength and durability.

Mixing Procedure

Accurate mixing is critical for achieving the desired consistency and performance of Sikadur 35. Follow the manufacturer’s instructions precisely for the correct ratio of components. Employ a clean mixing container and tools. Ensure thorough mixing to homogenize the components, creating a uniform mixture. This uniform mixture is crucial for obtaining the correct viscosity and chemical reaction for optimal results. Using a suitable mixing tool, like a spatula or drill with a mixing paddle, and ensuring proper mixing time will yield the best outcome.

Curing Times and Temperature Conditions

Curing times and temperature conditions significantly impact the final strength and properties of Sikadur 35. The recommended curing time is typically 24 hours at room temperature for the initial set. Full strength development often takes longer, usually several days, depending on environmental conditions. Elevated temperatures accelerate curing, while lower temperatures slow it down. The curing process is influenced by ambient humidity. Ensure the application area is maintained within the specified temperature range during the curing period to prevent issues. Consider using a humidity gauge and a thermometer to monitor the conditions.

Precautions and Safety Measures

Safety is paramount during the application process. Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a respirator, especially when handling the components or applying the material. Ventilation is crucial in confined spaces to minimize exposure to fumes. Ensure proper ventilation and adhere to the manufacturer’s safety data sheet (SDS) for detailed precautions. Work in a well-ventilated area and avoid any potential health risks during the application.

Application Methods Summary

| Application Method | Description | Pros | Cons |

|---|---|---|---|

| Method A: Trowel Application | Apply with a notched trowel for smooth and consistent coverage. | Suitable for various thicknesses and shapes; allows for precise placement. | Requires skill and practice; may not be ideal for large areas. |

| Method B: Gun Application | Use a cartridge gun for faster application of larger volumes. | Efficient for large areas; less labor-intensive. | Requires specialized equipment; may not be ideal for intricate shapes or precise placements. |

Step-by-Step Guide: Repairing a Concrete Crack

This guide demonstrates the application of Sikadur 35 to repair a concrete crack. The following steps illustrate a typical procedure.

- Surface Preparation: Clean the crack thoroughly, removing loose debris and dust. Remove any damaged concrete from the crack, ensuring a clean and sound substrate. Roughen the crack edges to improve adhesion.

- Mixing: Measure the components carefully according to the manufacturer’s instructions. Mix the components thoroughly until a uniform mixture is achieved. The mixture should be consistent throughout.

- Application: Apply the mixed Sikadur 35 to the crack, ensuring complete coverage. Work in small sections for efficient application. Smooth the surface using a trowel or other suitable tool. This will help achieve a uniform and strong repair.

- Curing: Allow the Sikadur 35 to cure for the recommended time and temperature conditions. Do not apply any stress or load during the curing period.

Material Properties

Source: static-src.com

Sikadur 35, a versatile epoxy-based adhesive, boasts exceptional performance across various applications. Understanding its material properties is crucial for selecting the right product and ensuring long-term durability. This section delves into the key chemical components, performance factors, adhesion mechanisms, and environmental impacts on its longevity.

Key Chemical Components

Sikadur 35 is primarily composed of epoxy resins, hardeners, and fillers. The specific blend of these components contributes to its unique characteristics. Epoxy resins provide the adhesive strength and flexibility, while hardeners catalyze the curing process, transforming the liquid resin into a strong, solid material. Fillers enhance mechanical properties and can influence the final appearance.

Factors Influencing Performance and Durability

Several factors impact the performance and durability of Sikadur 35. These include the quality and consistency of the raw materials, the curing conditions (temperature and humidity), and the substrate preparation. Proper surface preparation ensures optimal adhesion, minimizing the risk of failure. Curing at the recommended temperatures guarantees complete polymerization, resulting in the desired mechanical strength and chemical resistance.

Adhesion Mechanisms

Sikadur 35 adheres to various substrates through a complex interplay of chemical and mechanical forces. The epoxy resin’s ability to chemically bond with the substrate surface is key. This chemical bonding, coupled with mechanical interlocking with surface irregularities, creates a strong and durable bond.

Long-Term Performance Under Different Environmental Conditions

Sikadur 35 exhibits good resistance to a range of environmental factors. However, exposure to extreme temperatures, UV radiation, or aggressive chemicals can impact its performance. For applications in harsh environments, appropriate protection measures should be considered. For instance, in high-humidity areas, the use of protective coatings or coverings may be necessary.

Material Properties Table

This table summarizes the key material properties of Sikadur 35. These values are approximate and may vary depending on specific application parameters and batch variations.

| Property | Value | Unit |

|---|---|---|

| Tensile Strength | 50 | MPa |

| Compressive Strength | 100 | MPa |

| Elongation at Break | 5 | % |

| Flexural Strength | 35 | MPa |

| Shear Strength | 25 | MPa |

| Water Absorption | <1 | % |

Technical Specifications

Source: lpmexpress.com

Sikadur 35 boasts a robust set of technical specifications, ensuring reliable performance and safe handling. Understanding these details is crucial for proper application and achieving optimal results. This section provides a comprehensive overview of key specifications, storage requirements, and limitations to consider.

Product Packaging

The product is typically packaged in containers designed for safe handling and minimizing potential hazards. Specific packaging details, including container sizes and materials, are important to consider during procurement.

| Specification | Value |

|---|---|

| Container Type | Plastic drums, metal cans, or other suitable containers as per the specific order |

| Container Sizes | Various sizes available to meet project requirements |

| Packaging Materials | Durable and compatible with the product |

Storage and Handling, Sikadur 35

Proper storage and handling are vital to maintain product quality and safety. Adhering to these guidelines is critical for ensuring the longevity and integrity of Sikadur 35.

- Store in a cool, dry, and well-ventilated area, away from direct sunlight and extreme temperatures.

- Protect from moisture and freezing conditions to prevent potential damage.

- Always handle the product with appropriate safety precautions, including wearing protective gloves and eye protection.

- Use designated lifting equipment when handling large containers to prevent spills or accidental damage.

Shelf Life

Sikadur 35 has a defined shelf life, after which its performance characteristics may degrade. Understanding this limitation is essential for project planning and material procurement.

Shelf life is typically 12 months from the date of manufacture when stored under proper conditions. However, this may vary slightly depending on specific batch and storage conditions.

Material Properties

The material properties of Sikadur 35 are critical to its performance in various applications. These properties should be carefully considered when selecting the material for a particular project.

- Bond Strength: Sikadur 35 demonstrates high adhesion strength on various substrates. This is crucial for applications where strong bonding is essential. For example, in structural repairs, a high bond strength is essential for the integrity of the structure.

- Durability: The material exhibits excellent resistance to weathering and degradation, making it suitable for outdoor applications. For example, in bridges, the material’s resistance to weathering ensures the long-term functionality of the structure.

- Chemical Resistance: The material shows good resistance to various chemicals. For instance, in chemical plants, this resistance is critical for protecting the structural integrity of the infrastructure.

Certifications and Standards

Sikadur 35 adheres to relevant industry standards and certifications, ensuring its quality and safety. Meeting these standards is critical to ensuring the product’s performance and reliability.

- The product conforms to ISO 9001 standards for quality management systems.

- Specific certifications may vary depending on regional regulations and local authorities.

- Always check the specific documentation for the batch of Sikadur 35 for the applicable certifications and standards.

Case Studies & Examples

Source: imimg.com

Sikadur 35, a versatile epoxy adhesive, has proven its worth in a wide range of applications. Real-world case studies highlight its effectiveness in overcoming specific challenges, showcasing the significant benefits it brings to projects. This section delves into these successful applications, exploring the challenges, solutions, and advantages.

Successful applications of Sikadur 35 often stem from a deep understanding of the material’s properties and how they can be leveraged to address specific project needs. The diverse applications of Sikadur 35 underscore its importance in various industries, particularly where strong bonding and durability are critical.

Bridge Deck Repair

Sikadur 35 excels in repairing deteriorated bridge decks, often crucial for maintaining public infrastructure. Damaged concrete surfaces, frequently found on aging bridges, require robust repair solutions. Sikadur 35’s high tensile strength and resistance to weathering allow for durable repairs, ensuring the long-term integrity of the bridge. By effectively bonding with the existing concrete, Sikadur 35 provides a stable and reliable solution to prevent further deterioration and maintain traffic flow.

Concrete Restoration in Historic Buildings

Preserving historical structures demands meticulous restoration methods. Sikadur 35’s adhesion to various substrates, including concrete, makes it a suitable option for repairing and restoring historical buildings. The material’s ability to match the color and texture of existing concrete minimizes visual impact while enhancing the structural integrity of the building. This careful approach to restoration is critical for preserving the historical significance of these structures.

Industrial Flooring Repair

In industrial settings, efficient and durable flooring is essential for maintaining operational efficiency. Sikadur 35 effectively repairs damaged industrial flooring, offering a high-performance solution. The material’s resistance to chemicals and abrasion is critical in high-traffic areas, ensuring the longevity of the floor. By repairing cracks and imperfections, Sikadur 35 contributes to preventing costly downtime and maintaining the operational efficiency of the industrial environment.

Innovative Applications in Construction

Sikadur 35’s versatility extends beyond traditional applications. Imagine a scenario where complex structural elements need joining. Sikadur 35 can be creatively employed in assembling prefabricated components or repairing challenging structural elements. The material’s strong adhesive properties and rapid curing time can significantly expedite construction projects, reducing project timelines.

Role in Specific Industry Sectors

Sikadur 35 plays a crucial role in various industries, including:

- Construction: Sikadur 35 facilitates repairs and restorations on bridges, buildings, and other structures. Its robust bonding characteristics ensure lasting repairs, maintaining the structural integrity of the construction.

- Infrastructure: In infrastructure projects, Sikadur 35 offers a dependable solution for repairing and reinforcing critical elements, from bridges to tunnels. The material’s durability and chemical resistance are key factors in its suitability for demanding infrastructure applications.

- Manufacturing: Sikadur 35 provides a strong bonding solution in various manufacturing processes, enabling the assembly of complex components and equipment.

Final Review

Source: axiatekindo.com

In conclusion, Sikadur 35 stands out as a highly effective adhesive with impressive versatility. Its robust properties, coupled with straightforward application procedures, make it a practical choice for a wide range of construction and repair projects. From bonding various substrates to achieving long-lasting results, Sikadur 35 delivers. We hope this guide has provided you with a thorough understanding of this remarkable product, equipping you to confidently incorporate it into your next project.