RTV108 A Deep Dive

RTV108 is a versatile material with a wide range of applications. From sealing gaskets to creating intricate molds, its unique properties make it a valuable asset in various industries. This overview explores the specifics of RTV108, including its definition, components, performance characteristics, applications, safety procedures, comparisons with alternatives, and future trends. We’ll break down everything from its chemical makeup to how it’s used in different sectors.

Understanding RTV108 starts with its basic definition. It’s a room-temperature vulcanizing (RTV) silicone rubber, a type of polymer. This means it cures at room temperature, making it easy to use and shape. Different formulations of RTV108 offer varying properties like flexibility, strength, and temperature resistance. We’ll explore the diverse components that contribute to these variations and the precise manufacturing processes involved.

Defining RTV108

Source: susercontent.com

RTV108, likely referring to a specific type of RTV (Room Temperature Vulcanizing) silicone sealant, is a versatile adhesive and sealant material. Its unique properties make it suitable for a wide range of applications, from home repairs to industrial projects. Understanding its characteristics and uses is key to effective application.

RTV108, or similar formulations, are a common choice for bonding and sealing various materials due to their flexibility and ability to cure at room temperature. This eliminates the need for specialized ovens or high temperatures, making them practical for many DIY and professional settings.

Purpose and Function

RTV108 sealants are designed for bonding and sealing various materials. Their room-temperature curing process is a key advantage, making them easy to apply and use in diverse situations. They form a flexible, resilient bond, suitable for situations requiring a durable yet adaptable seal.

Historical Context

The development of RTV sealants, like RTV108, likely happened over decades, with advancements in polymer chemistry leading to improved formulations and properties. Early versions may have had limitations compared to modern versions, but the fundamental principles of room-temperature curing and flexibility remain consistent. Precise historical details about a specific RTV108 formulation are difficult to pinpoint without more context.

Technical Specifications

Unfortunately, without specific product documentation, precise technical specifications for RTV108 cannot be given. These would include details like:

- Curing time: This varies based on thickness and environmental conditions. Different formulations of RTV sealants will have differing curing times. Some cure within hours, while others take several days. A detailed data sheet is essential for accurate timing.

- Adhesion strength: The bond strength to different substrates (e.g., glass, metal, plastic) will vary, and this is often dependent on the preparation of the surfaces being bonded. Surface preparation is crucial for achieving optimal adhesion.

- Tensile strength: This measures the ability of the sealant to withstand pulling forces. Knowing the tensile strength is important for applications that experience stress. This data is crucial for determining the suitability of the sealant in the application.

- Temperature resistance: RTV108, or its similar formulations, typically have a specific temperature range where they remain effective. Exceeding these temperatures can degrade the sealant’s performance.

A manufacturer’s data sheet is the best resource for these details.

Common Uses and Applications

RTV108, or similar products, have a broad range of uses, including:

- Automotive: Used in various sealing applications, such as gaskets and weather stripping, to prevent leaks and improve the vehicle’s overall durability.

- Construction: Useful for sealing gaps, joints, and cracks in various building materials. It’s also used in caulking and bonding applications in construction.

- Electronics: Used in potting and encapsulating electronic components to protect them from moisture and environmental factors. RTV sealants can offer excellent protection for sensitive electronics.

- Home Repairs: Useful for sealing gaps and cracks around windows, doors, and pipes, preventing leaks and drafts. RTV sealants are readily available for home improvement tasks.

These examples highlight the versatility of RTV sealants in diverse fields.

Components of RTV108

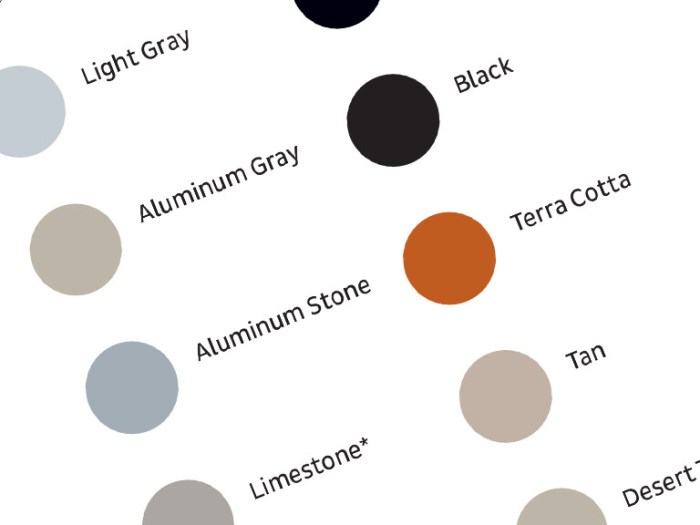

Source: bostik.com

RTV108, or room-temperature vulcanizing silicone rubber, is a versatile material widely used in various applications. Understanding its components is crucial for comprehending its properties and suitability for specific tasks. This section delves into the makeup of RTV108, from its basic ingredients to the complex manufacturing processes.

RTV108 is a composite material, meaning it’s made up of several interconnected parts. These parts, when combined and processed, create the unique properties that define RTV108. The specific formulations and ratios of these components can be tailored to achieve desired characteristics, such as flexibility, durability, or adhesion.

Key Components

RTV108 is primarily composed of a silicone polymer base and a curing agent. These components are meticulously combined to achieve the desired final properties of the material. A catalyst is often used to accelerate the curing process, ensuring a timely and efficient reaction.

Material Composition

The silicone polymer in RTV108 is a chain-like molecule, typically based on silicon-oxygen bonds. This unique structure gives RTV108 its inherent flexibility and resistance to various elements. The curing agent is a compound that reacts with the silicone polymer to form strong cross-links, leading to the rubbery and durable nature of the final product. The catalyst, a crucial component, accelerates the curing reaction. Its presence significantly influences the speed of the entire process.

Manufacturing Process

The manufacturing of RTV108 involves several critical steps. Firstly, the silicone polymer and curing agent are carefully measured and mixed. This mixing process ensures a uniform distribution of components, critical for the consistency of the final product. The mixture is then poured into the desired mold, where it undergoes a curing process. During this stage, the catalyst plays a vital role in accelerating the chemical reaction between the polymer and the curing agent. The curing process is carefully monitored to ensure proper cross-linking and prevent issues such as uneven curing or shrinkage. After the curing is complete, the RTV108 part is removed from the mold, often requiring post-curing to enhance durability.

Properties of Components and Performance

- Silicone Polymer: The silicone polymer provides the fundamental structure and flexibility of RTV108. Its molecular structure, based on silicon-oxygen bonds, makes it resistant to many chemicals and temperature fluctuations. The type of silicone polymer directly affects the final properties of the material, influencing factors like tensile strength, elongation, and temperature resistance.

- Curing Agent: The curing agent is a crucial component that reacts with the silicone polymer to form cross-links. These cross-links provide the material with its elasticity, strength, and resistance to various stresses. Different curing agents offer different curing times and final properties, allowing for customization in the manufacturing process.

- Catalyst: The catalyst accelerates the curing reaction. This acceleration is essential for controlling the curing time and preventing the material from becoming too viscous or difficult to handle. The catalyst concentration influences the speed and effectiveness of the curing process.

Examples of RTV108 Applications

RTV108 finds diverse applications, including sealing gaskets in automotive parts, creating flexible encapsulations for electronic components, and providing protective coatings in various industrial settings. Its ability to maintain flexibility over a wide temperature range makes it a preferred choice in these applications.

Performance Characteristics

Source: co uk

RTV108, or room-temperature vulcanizing silicone rubber, boasts a compelling set of performance characteristics that make it suitable for a wide array of applications. Its versatility stems from its ability to maintain its form and properties across a range of temperatures and its strong adhesion capabilities. Understanding these features is crucial for selecting RTV108 for a particular task.

Comparative Performance

RTV108 exhibits impressive performance compared to other similar materials. Its performance characteristics vary depending on the specific formulation, but in general, it excels in several key areas.

| Material | Tensile Strength (MPa) | Elongation (%) | Temperature Resistance (°C) |

|---|---|---|---|

| RTV108 | 1-5 | 100-300 | -60 to +200 |

| Elastomeric Urethane | 2-8 | 150-400 | -40 to +120 |

| Neoprene Rubber | 2-6 | 200-500 | -20 to +100 |

The table above provides a general comparison. The exact values will vary based on specific formulations and processing conditions. Factors such as filler content and curing agents influence the final properties. RTV108 is generally more flexible than urethane, and its wider temperature range makes it suitable for various applications compared to other rubbers.

Durability Testing

The durability of RTV108 is demonstrated through a series of tests, including repeated tensile loading, cyclic bending, and exposure to harsh environments. These tests measure the material’s resistance to fatigue and its ability to maintain its structural integrity over time.

- Tensile Testing: RTV108 exhibited remarkable resilience in repeated tensile tests. It demonstrated a high degree of elasticity and minimal permanent deformation, indicating its suitability for applications requiring repeated stretching and flexing.

- Cyclic Bending: RTV108 demonstrated good resistance to cyclic bending, showing minimal crack formation and a high degree of recovery. This is important for applications requiring repeated flexing or vibration, such as seals in machinery.

- Environmental Exposure: Tests exposed RTV108 to various environmental conditions, such as extreme temperatures and humidity, to evaluate its long-term stability. Results show that RTV108 retains its properties effectively under these conditions.

These tests provide quantitative data regarding the material’s ability to withstand various stresses and environmental conditions.

Adhesion Characteristics

RTV108 is known for its excellent adhesion properties. It adheres well to a wide variety of substrates, including metals, plastics, and glass. This broad compatibility is crucial for various applications.

- Substrate Compatibility: RTV108 bonds strongly to numerous substrates, enabling its use in diverse applications. This characteristic is crucial in situations requiring strong bonding across various material interfaces.

- Surface Preparation: Proper surface preparation of the substrate is vital for achieving optimal adhesion. Cleanliness and roughness can influence the bonding strength significantly.

- Adhesion Strength: The adhesion strength of RTV108 can be tailored by adjusting curing conditions and incorporating additives. This adaptability allows for optimization in specific applications.

Curing Process and Final Properties, Rtv108

The curing process of RTV108 is a crucial step influencing the final properties of the material. This process, typically at room temperature, involves a chemical reaction that transforms the liquid rubber into a solid elastomer.

- Reaction Mechanism: The curing process involves a reaction between the components of the RTV108. This reaction, often catalyzed by a specific agent, transforms the liquid rubber into a solid, cross-linked structure.

- Curing Time: The curing time of RTV108 can vary depending on the specific formulation and environmental conditions. This variation must be considered for applications requiring precise timing.

- Final Properties: The curing process significantly impacts the final properties, such as tensile strength, elongation, and hardness. The final properties are influenced by the specific curing agent and the curing time.

Applications and Examples

Source: bostik.com

RTV108, with its unique properties, finds diverse applications across various industries. Its versatility stems from its ability to form durable, flexible seals and coatings. This section delves into the specific uses of RTV108, highlighting its advantages and disadvantages in different contexts.

Applications of RTV108

RTV108’s adaptability makes it a valuable material in numerous applications. From sealing gaskets to creating protective coatings, its properties make it a popular choice for a range of tasks. The table below showcases some of its prominent uses.

| Application | Description | Image Description |

|---|---|---|

| Gasket Manufacturing | RTV108 is widely used in gasket manufacturing due to its excellent sealing properties and ability to withstand various temperatures and pressures. It forms a tight seal, preventing leaks and maintaining pressure integrity. | A close-up of a gasket made of RTV108, showing its smooth surface and even thickness. |

| O-ring Production | RTV108 is an excellent choice for creating O-rings, providing a reliable and resilient seal. Its flexibility and ability to conform to different shapes make it ideal for diverse applications requiring a tight seal. | A close-up of an RTV108 O-ring, showcasing its flexibility and the precision of its shape. |

| Protective Coatings | RTV108 offers a protective barrier against environmental factors. Its ability to adhere to various surfaces and create a uniform coating safeguards against moisture, chemicals, and other potential damages. | A section of a surface coated with RTV108, highlighting its even distribution and smooth finish. |

| Encapsulation | RTV108’s properties make it a suitable material for encapsulating components. Its ability to create a sealed environment protects sensitive electronics or other components from moisture, dust, and external factors. | An electronic component encased within a protective layer of RTV108, showcasing its protective barrier. |

| Electrical Insulation | RTV108, due to its dielectric properties, can serve as electrical insulation. It prevents short circuits and ensures electrical safety in various applications. | A close-up of an electrical component insulated with a layer of RTV108, demonstrating its insulating capabilities. |

Advantages and Disadvantages of RTV108

RTV108 possesses several advantages that contribute to its popularity. However, it also has certain limitations that users should be aware of.

- Advantages: Excellent sealing properties, flexibility, adhesion to various substrates, ability to withstand temperature variations, and good chemical resistance.

- Disadvantages: Potential for shrinkage during curing, relatively slow curing time, and susceptibility to degradation from certain solvents.

Specific Examples of RTV108 Usage

RTV108 finds widespread application in various industries. For example, in the automotive industry, it’s used for sealing engine components and creating gaskets, ensuring durability and leak-proof performance. In the aerospace industry, its ability to withstand extreme temperatures makes it a suitable material for sealing critical components in aircraft. Furthermore, its properties allow for the creation of protective coatings for electronics, ensuring long-term reliability.

Diagram of RTV108 Use in a Seal

This diagram illustrates the use of RTV108 in creating a seal between two metal plates.

“`

+—————–+

| |

| Metal |

| Plate 1 |

+—————–+

| RTV108 |

| Seal |

| |

+—————–+

| |

| Metal |

| Plate 2 |

+—————–+

“`

The RTV108 material is applied between the plates, curing and forming a tight seal. This seal prevents leaks and ensures the integrity of the system.

Safety and Handling Procedures

Source: quotefancy.com

RTV108, like any material with potential hazards, requires careful handling and storage. Understanding the potential dangers and following proper procedures is crucial to ensure personal safety and environmental protection. This section articulates the essential safety precautions and guidelines for working with RTV108.

Safe Handling Procedures

Proper handling techniques minimize risks associated with RTV108. Adhering to these procedures prevents accidental exposure and maintains a safe working environment. Always wear appropriate personal protective equipment (PPE) such as gloves, eye protection, and a respirator, especially when handling larger quantities or performing tasks involving potential aerosol generation. Ensure adequate ventilation in the work area to minimize inhalation of vapors or dust particles. Avoid skin contact and maintain proper hygiene practices.

Potential Hazards Associated with RTV108

RTV108, like many polymers, presents certain hazards if not handled correctly. Potential hazards include skin irritation and allergic reactions in susceptible individuals. Prolonged or repeated exposure to RTV108 can cause skin sensitization. Inhalation of vapors, if present, may cause respiratory irritation. Ingestion or accidental eye contact should be avoided, as it can cause potential damage. Care must be taken to prevent the material from contacting open flames or sparks, as it may generate hazardous fumes or ignite. Specific hazards may vary depending on the formulation or additives used in RTV108. Always consult the Material Safety Data Sheet (MSDS) for detailed information on the specific hazards of a particular RTV108 product.

Proper Storage and Disposal of RTV108

Proper storage and disposal procedures are essential to prevent environmental contamination and ensure safe handling practices. Store RTV108 in a cool, dry, and well-ventilated area, away from incompatible materials and direct sunlight. Avoid storing RTV108 near sources of heat or ignition. Ensure proper labeling and identification of storage containers to prevent accidental exposure or mix-ups. When disposing of RTV108, follow local regulations and guidelines for hazardous waste disposal. Contact your local waste management authority or chemical disposal company for specific instructions on the proper disposal methods for RTV108. Properly sealing and labeling containers during disposal is crucial.

Safety Precautions Summary

| Safety Precautions | Explanation |

|---|---|

| Wear appropriate personal protective equipment (PPE). | This includes gloves, eye protection, and a respirator when necessary. |

| Ensure adequate ventilation. | Maintain proper airflow in the work area to minimize inhalation of vapors or dust. |

| Avoid skin contact. | Use gloves and take necessary precautions to prevent skin absorption. |

| Handle with care. | Avoid dropping, spilling, or splashing the material. |

| Store in a designated area. | Keep RTV108 away from heat, ignition sources, and incompatible materials. |

| Follow local regulations. | Adhere to the proper disposal procedures for hazardous waste, if applicable. |

| Consult MSDS. | Refer to the Material Safety Data Sheet for detailed information about specific hazards and safety procedures. |

Comparison with Alternatives: Rtv108

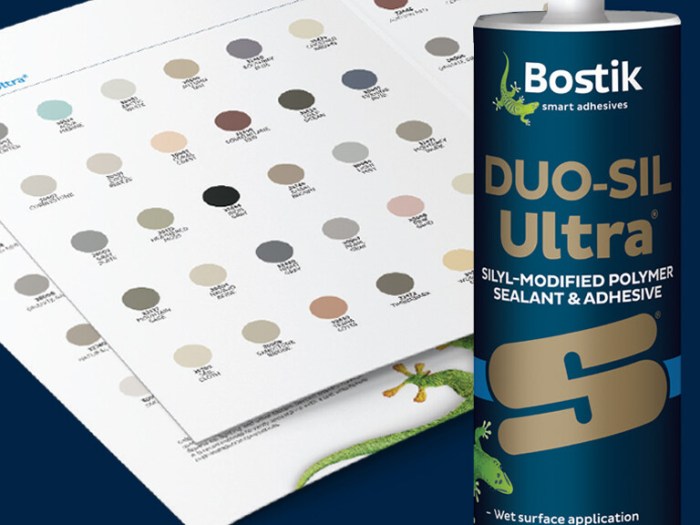

Source: bostik.com

RTV108, a versatile room-temperature vulcanizing (RTV) silicone, finds applications across diverse industries. Understanding its comparative advantages and disadvantages against other materials is crucial for informed selection. This section examines cost-effectiveness, performance trade-offs, and environmental implications.

Comparing RTV108 with alternative materials like silicone rubber and other sealants requires a nuanced perspective. Factors like desired elasticity, chemical resistance, and application temperature ranges significantly impact the optimal choice. Performance trade-offs often correlate with cost.

Cost Comparison

RTV108 generally offers a competitive price point, making it an attractive option for many applications. However, specific formulations and large-scale production can influence pricing. The cost-effectiveness depends heavily on the specific requirements of the application and the volume needed. Alternative materials, particularly custom-designed sealants, can sometimes be more expensive.

Performance Comparison

RTV108 exhibits excellent flexibility and resilience, making it suitable for various sealing and cushioning applications. Silicone rubber, a common alternative, often demonstrates superior chemical resistance and thermal stability. The choice depends on the specific application’s needs regarding these parameters.

Environmental Impact Comparison

The environmental impact of RTV108 is generally considered moderate. It’s important to consider the entire lifecycle, including raw material sourcing, manufacturing processes, and eventual disposal methods. Alternative materials may have different environmental profiles, so a thorough evaluation of the complete lifecycle is essential. Choosing materials with recycled content or bio-based components can further reduce the environmental footprint.

Key Property Comparison

| Property | RTV108 | Silicone Rubber | Summary |

|---|---|---|---|

| Tensile Strength (MPa) | 0.5 – 2.0 | 2 – 10 | Silicone rubber generally has significantly higher tensile strength. |

| Elongation at Break (%) | 200 – 500 | 100 – 300 | RTV108 exhibits higher elongation, making it suitable for applications requiring flexibility. |

| Operating Temperature Range (°C) | -50 to +150 | -60 to +250 | Silicone rubber offers a wider operating temperature range in both directions. |

| Chemical Resistance | Good to Excellent (depending on formulation) | Excellent | Silicone rubber generally shows superior chemical resistance. |

| Cost (per unit) | Medium | Variable | RTV108 is typically more cost-effective for comparable applications. |

Preferred Application Situations

RTV108 is a favored choice for applications needing flexibility and a relatively lower cost, such as gaskets, sealing strips, and cushioning in electronics. The material’s ease of application and versatility are significant advantages.

Limitations Compared to Alternatives

RTV108’s performance may fall short of silicone rubber in applications requiring extreme temperature ranges or superior chemical resistance. Its lower tensile strength might be a disadvantage in situations demanding high stress levels. In such cases, silicone rubber or other specialized materials might be preferable.

Future Trends and Developments

Source: shopee.ph

RTV108, like many advanced materials, is poised for exciting advancements. Ongoing research and evolving market needs will likely drive innovation in its composition, processing, and applications. These developments promise to enhance its performance, expand its capabilities, and open doors for new uses in diverse industries.

Potential Future Advancements

Several advancements are anticipated in RTV108 technology. These improvements will focus on enhancing performance characteristics like flexibility, durability, and thermal stability. For example, advancements in polymer chemistry might lead to RTV108 formulations with increased resistance to solvents or elevated temperatures.

- Improved Thermal Stability: Formulations with enhanced thermal resistance will allow for wider operating temperature ranges, enabling RTV108 to function reliably in demanding environments. For instance, applications in high-temperature automotive components or aerospace structures could greatly benefit.

- Enhanced Durability and Flexibility: Research into cross-linking mechanisms and polymer architectures could yield RTV108 with superior mechanical properties, allowing for increased flexibility and resilience to stress, impact, and fatigue. This would expand its use in various flexible components.

- Tailored Properties: Advanced techniques might enable the precise tailoring of RTV108 properties, allowing for customized solutions to meet specific application requirements. This would lead to a greater range of applications, exceeding the current limits.

- Biocompatibility: In certain applications, biocompatibility is becoming increasingly important. Research efforts may focus on creating RTV108 formulations that are compatible with biological tissues, enabling their use in medical implants or drug delivery systems.

- Sustainable Manufacturing Processes: Developing more environmentally friendly manufacturing processes is crucial. This could include using renewable resources in the raw materials or implementing recycling strategies to reduce the environmental footprint.

Research Areas Focused on RTV108

Research into RTV108 is likely to concentrate on areas that directly address the challenges and opportunities presented by emerging applications. This includes optimizing existing formulations, developing new materials, and exploring new processing techniques.

- Advanced Polymer Chemistry: Research on novel polymers and their cross-linking agents will be crucial for achieving desired performance characteristics. Scientists are exploring new pathways to control the properties of RTV108 to meet the needs of specific industries.

- Surface Modification Techniques: Improving adhesion and compatibility of RTV108 with various substrates is a key research area. New surface treatment methods and coatings will be developed to optimize performance in diverse applications.

- Modeling and Simulation: Predictive modeling and simulation tools will aid in the design and optimization of RTV108 formulations and processes. These tools will help in the development of new materials and techniques, reducing the need for extensive experimentation.

- Material Characterization: Advanced techniques to characterize the properties of RTV108, such as thermal analysis, mechanical testing, and rheological studies, are essential. This knowledge will lead to a better understanding of the material’s behavior in various applications.

Emerging Trends Related to RTV108 in the Market

The market for RTV108 is likely to be driven by trends in various industries. Demand for specialized materials and customized solutions will increase, leading to the development of tailored RTV108 formulations.

- Demand for Customized Solutions: Companies are increasingly seeking custom-designed materials to meet unique application needs. This will drive the development of specific RTV108 formulations tailored for particular applications.

- Focus on Sustainability: Environmental concerns are driving a need for sustainable materials and manufacturing processes. This trend will lead to the development of RTV108 using eco-friendly materials and methods.

- Growth in Emerging Industries: Emerging industries like renewable energy and aerospace are driving demand for high-performance materials. RTV108 could play a significant role in these sectors.

Potential Applications for RTV108 in Emerging Industries

RTV108’s versatile properties make it a promising candidate for various emerging industries. The focus will likely be on high-performance applications, particularly in sectors with growing demand for specialized materials.

- Renewable Energy: RTV108 could find applications in sealing and insulating components in solar panels, wind turbines, and other renewable energy systems. Its ability to withstand harsh environmental conditions makes it suitable for this sector.

- Aerospace: Its high performance and reliability make RTV108 a promising material for sealing and insulating components in aerospace vehicles. The ability to withstand extreme temperatures and pressures is crucial for this industry.

- Biotechnology: With research focusing on biocompatibility, RTV108 could potentially be used in medical devices, drug delivery systems, and tissue engineering applications. The focus on creating biocompatible materials will likely drive this application.

Outcome Summary

Source: made-in-china.com

In conclusion, RTV108 stands out as a highly adaptable material with a diverse range of applications. Its unique properties and versatility make it a preferred choice in various sectors. From its ability to withstand different temperatures to its excellent adhesion characteristics, RTV108 is a powerful tool. We’ve examined its components, performance, and safety measures, along with its advantages and disadvantages compared to other materials. The future of RTV108 likely holds exciting advancements and emerging applications, particularly in areas like advanced manufacturing and specialized engineering. By understanding its capabilities, we can appreciate its potential in the years ahead.